Abstract

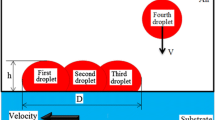

Droplet based additive manufacturing is a branch of novel processes to build full dense metal parts by adding material droplet by droplet on a build platform. As each droplet solidifies individually upon contact, the quality of bonding to the existing material is determined by the adjacent surface temperatures and the temperature of the arriving droplet. To design a manufacturing process that ensures good bonds between all droplets, it is necessary to understand the relations between process parameters, the part’s geometry and thermal conditions for each arriving droplet. This paper presents a thermal simulation model that is based on Flow 3D software. By adding a user routine to the solver, it is possible to simulate the building process of a part consisting of several thousand droplets with an acceptable effort. This simulation is used to study the effect of production parameters (substrate temperature, droplet temperature and deposition frequency) as well as the parts geometry (layer size and height) on the resultant temperature field. The model was successfully validated with experimental data and can deliver valuable information during further development of this additive manufacturing process.

Similar content being viewed by others

Abbreviations

- T :

-

Temperature

- \(\rho\) :

-

Density

- c :

-

Heat capacity

- \(\lambda\) :

-

Thermal conductivity

- a :

-

Thermal diffusivity

- L :

-

Latent heat of fusion

- F :

-

Fraction of fluid

- \(f_s\) :

-

Fraction solid

- A :

-

Cell surface area

- \(\alpha\) :

-

Heat transfer coefficient

- m :

-

Melting point

- x, y, z :

-

Coordinate directions

- subs :

-

Substrate

- drop :

-

Droplet

- eff :

-

Effective

- w :

-

Wall

References

Bernhard F (2014) Handbuch der Technischen Temperaturmessung, 2nd edn. VDI-Buch, Springer Vieweg, Berlin

Cao W, Miyamoto Y (2006) Freeform fabrication of aluminum parts by direct deposition of molten aluminum. J Mater Process Technol 173(2):209–212. https://doi.org/10.1016/j.jmatprotec.2005.11.028

Chao Y, Qi L, Xiao Y, Luo J, Zhou J (2012) Manufacturing of micro thin-walled metal parts by micro-droplet deposition. J Mater Process Technol 212(2):484–491. https://doi.org/10.1016/j.jmatprotec.2011.10.015

Chao Y, Qi L, Zuo H, Luo J, Hou X, Li H (2013) Remelting and bonding of deposited aluminum alloy droplets under different droplet and substrate temperatures in metal droplet deposition manufacture. Int J Mach Tool Manuf 69:38–47. https://doi.org/10.1016/j.ijmachtools.2013.03.004

Chao Y, Qi L, Bai Z (2016) 3d dynamic simulation analysis of thermal–mechanical coupling during 7075 aluminum alloy micro-droplet deposition manufacture. Rare Met Mater Eng 45(8):1924–1930. https://doi.org/10.1016/S1875-5372(16)30148-5

Du J, Wei Z (2015) Numerical analysis of pileup process in metal microdroplet deposition manufacture. Int J Therm Sci 96:35–44. https://doi.org/10.1016/j.ijthermalsci.2015.04.016

Fang M, Chandra S, Park CB (2008) Building three-dimensional objects by deposition of molten metal droplets. Rapid Prototyping J 14(1):44–52. https://doi.org/10.1108/13552540810841553

Fang M, Chandra S, Park CB (2009) Heat transfer during deposition of molten aluminum alloy droplets to build vertical columns. J Heat Transf 131(11):1–7. https://doi.org/10.1115/1.3156782

Ghafouri-Azar R, Shakeri S, Chandra S, Mostaghimi J (2003) Interactions between molten metal droplets impinging on a solid surface. Int J Heat Mass Transf 46(8):1395–1407. https://doi.org/10.1016/S0017-9310(02)00403-9

Haferl S, Poulikakos D (2003) Experimental investigation of the transient impact fluid dynamics and solidification of a molten microdroplet pile-up. Int J Heat Mass Transf 46:535–550

Hirt C, Nichols B (1981) Volume of fluid (vof) method for the dynamics of free boundaries. J Comput Phys 39(1):201–225. https://doi.org/10.1016/0021-9991(81)90145-5

Karampelas I, Vader S, Vader Z, Sukhotskiy V, Verma A, Garg G, Tong M, Furlani E (2017) Drop-on-demand 3D metal printing. In: Laudon M, Romanowicz B (eds) TechConnect briefs 2017, TechConnect, Danville, CA, USA

Li H, Wang P, Qi L, Zuo H, Zhong S, Hou X (2012) 3d numerical simulation of successive deposition of uniform molten al droplets on a moving substrate and experimental validation. Comput Mater Sci 65:291–301. https://doi.org/10.1016/j.commatsci.2012.07.034

Li H, Li H, Qi L, Jun LUO, Zuo H (2014) Simulation on deposition and solidification processes of 7075 al alloy droplets in 3d printing technology. Trans Nonferrous Met Soc 24(6):1836–1843. https://doi.org/10.1016/S1003-6326(14)63261-1

Li S, Wei Z, Du J, Zhao G, Wang X, Lu B (2016) Numerical and experimental investigation of molten metal droplet deposition applied to rapid prototyping. Appl Phys A 122(8):146. https://doi.org/10.1007/s00339-016-0264-8

Liu Q, Orme M (2001) On precision droplet-based net-form manufacturing technology. Proc Inst Mech Eng 215(10):1333–1355. https://doi.org/10.1243/0954405011519123

Luo J, Yang F, Zhong S, Qi L (2014) Modelling of uniform micron-sized metal particles production using harmonic mechanical excitation. Proc Eng 81:1312–1317. https://doi.org/10.1016/j.proeng.2014.10.149

Mills KC (2002) Recommended Values of thermophysical properties for commercial alloys. Woodhead Publishing, Cambridge

Pasandideh-Fard M, Bhola R, Chandra S, Mostaghimi J (1998) Deposition of tin droplets on a steel plate: simulations and experiments. Int J Heat Mass Transf 41(19):2929–2945. https://doi.org/10.1016/s0017-9310(98)00023-4

Polifke W, Kopitz J (2009) Wärmeübertragung, 2nd edn. Pearson Studium, Munich

Rumschoettel D, Kunzel F, Irlinger F, Lueth TC (2016) A novel piezoelectric printhead for high melting point liquid metals. In: 2016 Pan-Pacific microelectronics symposium. IEEE, pp 1–8. https://doi.org/10.1109/PanPacific.2016.7428392

Rumschoettel D, Griebel B, Irlinger F, Lueth TC (2017) A fast pneumatic droplet generator for the ejection of molten aluminum. In: 2017 Pan-Pacific microelectronics symposium. IEEE, Piscataway, NJ

Schiaffino S, Sonin AA (1997) Motion and arrest of a molten contact line on a cold surface: an experimental study. Phys Fluids 9(8):2217. https://doi.org/10.1063/1.869344

Tseng AA, Lee MH, Zhao B (2001) Design and operation of a droplet deposition system for freeform fabrication of metal parts. J Eng Mater Technol ASME 123(1):74–84. https://doi.org/10.1115/1.1286187

Wang SP, Wang GX, Matthys EF (1998) Melting and resolidification of a substrate in contact with a molten metal: operational maps. Int J Heat Mass Transf 41(10):1177–1188. https://doi.org/10.1016/S0017-9310(97)00222-6

Wang T, Kwok TH, Zhou C (2017) In-situ droplet inspection and control system for liquid metal jet 3d printing process. Proc Manuf 10:968–981. https://doi.org/10.1016/j.promfg.2017.07.088

Zhang D, Qi L, Luo J, Yi H, Hou X (2017) Direct fabrication of unsupported inclined aluminum pillars based on uniform micro droplets deposition. Int J Mach Tools Manuf 116:18–24. https://doi.org/10.1016/j.ijmachtools.2017.01.001

Zhao Z, Poulikakos D, Fukai J (1996) Heat transfer and fluid dynamics during the collision of a liquid droplet on a substrate—I. Modeling. Int J Heat Mass Transf 39(13):2771–2789. https://doi.org/10.1016/0017-9310(95)00305-3

Zhao Z, Poulikakos D, Fukai J (1996) Heat transfer and fluid dynamics during the collision of a liquid droplet on a substrate—II. Experiments. Int J Heat Mass Transf 39(13):2791–2802. https://doi.org/10.1016/0017-9310(95)00306-1

Hs Zuo, Hj Li, Qi Lh, Luo J, Zhong Sy, Wu Yf (2015) Effect of non-isothermal deposition on surface morphology and microstructure of uniform molten aluminum alloy droplets applied to three-dimensional printing. Appl Phys A 118(1):327–335. https://doi.org/10.1007/s00339-014-8735-2

Acknowledgements

This work was funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) under Grant no. LU 604/42-1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Himmel, B., Rumschöttel, D. & Volk, W. Thermal process simulation of droplet based metal printing with aluminium. Prod. Eng. Res. Devel. 12, 457–464 (2018). https://doi.org/10.1007/s11740-018-0819-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-018-0819-y