Abstract

Negative extensibility metamaterials are able to contract against the line of increasing external tension. A bistable unit cell exhibits several nonlinear mechanical behaviors including the negative extensibility response. Here, an exact form of the total mechanical potential is used based on engineering strain measure. The mechanical response is a function of the system parameters that specify unit cell dimensions and member stiffnesses. A phase diagram is calculated, which maps the response to regions in the diagram using the system parameters as the coordinate axes. Boundary lines pinpoint the onset of a particular mechanical response. Contour lines allow various material properties to be fine-tuned. Analogous to thermodynamic phase diagrams, there exist singular “triple points” which simultaneously satisfy conditions for three response types. The discussion ends with a brief statement about how thermodynamic phase diagrams differ from the phase diagram in this paper.

Similar content being viewed by others

References

Klatt T, Haberman MR (2013) A nonlinear negative stiffness metamaterial unit cell and small-on-large multiscale material model. J Appl Phys 114(3):033503

Wu Y, Lai Y, Zhang ZQ (2011) Elastic metamaterials with simultaneously negative effective shear modulus and mass density. Phys Rev Lett 107(10):105506

Qu J, Kadic M, Wegener M (2017) Poroelastic metamaterials with negative effective static compressibility. Appl Phys Lett 110(17):171901

Babaee S, Shim J, Weaver JC, Chen ER, Patel N, Bertoldi K (2013) 3D Soft metamaterials with negative Poisson’s ratio. Adv Mater 25(36):5044

Bückmann T, Stenger N, Kadic M, Kaschke J, Frölich A, Kennerknecht T, Eberl C, Thiel M, Wegener M (2012) Tailored 3D mechanical metamaterials made by dip-in direct-laser-writing optical lithography. Adv Mater 24(20):2710

Bückmann T, Thiel M, Kadic M, Schittny R, Wegener M (2014) An elasto-mechanical unfeelability cloak made of pentamode metamaterials. Nat Commun 5:4130

Wang K, Zhao Y, Chang YH, Qian Z, Zhang C, Wang B, Vannan MA, Wang MJ (2016) Controlling the mechanical behavior of dual-material 3D printed meta-materials for patient-specific tissue-mimicking phantoms. Mater Des 90:704

Coulais C, Sounas D, Alù A (2017) Static non-reciprocity in mechanical metamaterials. Nature 542:461

Lakes R (2001) Extreme damping in compliant composites with a negative-stiffness phase. Philos Mag Lett 81(2):95

Lakes R, Rosakis P, Ruina A (1993) Microbuckling instability in elastomeric cellular solids. J Mater Sci 28(17):4667

Moore B, Jaglinski T, Stone D, Lakes R (2006) Negative incremental bulk modulus in foams. Philos Mag Lett 86(10):651

Nicolaou ZG, Motter AE (2012) Mechanical metamaterials with negative compressibility transitions. Nat Mater 11(7):608

Jaglinski T, Kochmann D, Stone D, Lakes R (2007) Composite materials with viscoelastic stiffness greater than diamond. Science 315(5812):620

Lakes R, Wojciechowski K (2008) Negative compressibility, negative Poisson’s ratio, and stability. Physica Status Solidi (b) 245(3):545

Dyskin AV, Pasternak E (2012) Elastic composite with negative stiffness inclusions in antiplane strain. Int J Eng Sci 58:45

Silverberg JL, Evans AA, McLeod L, Hayward RC, Hull T, Santangelo CD, Cohen I (2014) Using origami design principles to fold reprogrammable mechanical metamaterials. Science 345(6197):647

Boatti E, Vasios N, Bertoldi K (2017) Origami metamaterials for tunable thermal expansion. Adv Mater 29:1700360

Chen Y, Li T, Scarpa F, Wang L (2017) Lattice metamaterials with mechanically Tunable Poisson’s ratio for vibration control. Phys Rev Appl 7(2):024012

Chen M, Karpov E (2014) Bistability and thermal coupling in elastic metamaterials with negative compressibility. Phys Rev E 90(3):033201

Harne RL, Wu Z, Wang KW (2016) Designing and harnessing the metastable states of a modular Metastructure for programmable mechanical properties adaptation. J Mech Des 138(2):021402

Che K, Yuan C, Wu J, Qi HJ, Meaud J (2017) Three-dimensional-printed multistable mechanical metamaterials with a deterministic deformation sequence. J Appl Mech 84(1):011004

Liu A, Zhu W, Tsai D, Zheludev NI (2012) Micromachined tunable metamaterials: a review. J Opt 14(11):114009

Rafsanjani A, Akbarzadeh A, Pasini D (2015) Snapping mechanical metamaterials under tension. Adv Mater 27(39):5931

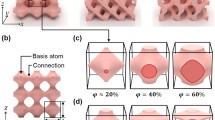

Karpov EG, Danso LA, Klein JT (2017) Negative extensibility metamaterials: occurrence and design-space topology. Phys Rev E 96(2):023002

Otsuka K, Wayman CM (1999) Shape memory materials. Cambridge University Press, Cambridge

Dong J, Cai C, Okeil AM (2010) Overview of potential and existing applications of shape memory alloys in bridges. J Bridge Eng 16(2):305

Zeeman EC (1977) Catastrophe theory: selected papers, 1972–1977. Addison-Wesley, Boston

Saunders PT (1980) An introduction to catastrophe theory. Cambridge University Press, Cambridge

Gilmore R (1993) Catastrophe theory for scientists and engineers. Courier Corporation, North Chelmsford

Liu WK, Karpov E, Zhang S, Park H (2004) An introduction to computational nanomechanics and materials. Comput Methods Appl Mech Eng 193(17):1529

Kan Q, Yu C, Kang G, Li J, Yan W (2016) Experimental observations on rate-dependent cyclic deformation of super-elastic NiTi shape memory alloy. Mech Mater 97:48

Ortın J, Delaey L (2002) Hysteresis in shape-memory alloys. Int J Non-Linear Mech 37(8):1275

Dolce M, Cardone D (2001) Mechanical behaviour of shape memory alloys for seismic applications 1. Martensite and austenite NiTi bars subjected to torsion. Int J Mech Sci 43(11):2631

Saadat S, Salichs J, Noori M, Hou Z, Davoodi H, Bar-On I, Suzuki Y, Masuda A (2002) An overview of vibration and seismic applications of NiTi shape memory alloy. Smart Mater Struct 11(2):218

Liu WK, Karpov EG, Park HS (2009) Nano mechanics and materials: theory, multiscale methods and applications. Wiley, Hoboken

Lukas HL, Fries SG, Sundman B (2007) Computational thermodynamics: the Calphad method. Cambridge University Press, Cambridge

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Klein, J.T., Karpov, E.G. Negative extensibility metamaterials: phase diagram calculation. Comput Mech 62, 669–683 (2018). https://doi.org/10.1007/s00466-017-1520-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-017-1520-2