Abstract

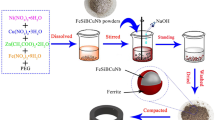

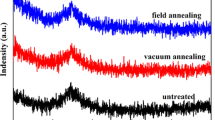

In this study, the melt spinning method was used to develop Fe80.5Si7.5B6Nb5Cu amorphous ribbons in the first step. Then, the Fe80.5Si7.5B6Nb5Cu amorphous-nanocrystalline core with a compact microstructure was obtained by multiple processes. The main properties of the magnetic powder core, such as micromorphology, thermal behavior, permeability, power loss and quality factor, have been analyzed. The obtained results show that an Fe80.5Si7.5B6Nb5Cu amorphous-nanocrystalline duplex core has high permeability (54.8–57), is relatively stable at different frequencies and magnetic fields, and the maximum power loss is only 313 W/kg; furthermore, it has a good quality factor.

Similar content being viewed by others

References

D.C. Jiles, Acta Mater. 51, 5907 (2003).

J. Guo, Y. Dong, Q. Man, Q. Li, C. Chang, and X.M. Wang, J. Magn. Magn. Mater. 401, 432 (2016).

Y. Liu, D.J. Sellmyer, and D. Shindo, Handbook of advanced magnetic materials, 1st ed. (Boston: Springer, 2006).

W.J. Yuan, S.J. Pang, F.J. Liu, and T. Zhang, J. Alloy. Compd. 504, S142 (2010).

Y. Han, C.T. Chang, S.L. Zhu, A. Inoue, D.V. Louzguine-Luzgin, E. Shalaan, and F. Al-Marzouki, Intermetallics 54, 169 (2014).

S. Yoshida, T. Mizushima, T. Hatanai, and A. Inoue, IEEE Trans. Magn. 36, 3424 (2000).

Y. Youshizawa, S. Oguma, and K. Yamauchi, J. Appl. Phys. 64, 6044 (1988).

H. Shokrollahi and K. Janghorban, J. Mater. Process. Technol. 189, 1 (2007).

F.G. Chen, Y.G. Wang, X.F. Miao, H. Hong, and K. Bi, J. Alloy. Compd. 549, 26 (2013).

R. Nowosielski, J.J. Wyslocki, I. Wnuk, P. Sakiewicz, and P. Grammatyka, J. Mater. Process. Technol. 162, 242 (2005).

T.H. Kim, K.K. Jee, Y.B. Kim, D.J. Byun, and J.H. Han, J. Magn. Magn. Mater. 322, 2423 (2010).

J. Zhou, Y.F. Cui, H.S. Liu, W. Wang, K. Peng, and Y.D. Xiao, J. Mater. Sci. 46, 7567 (2011).

J.S. Huang, Y.C. Xu, Z.Y. Wang, F.U. Min, and Z.P. Pan, J. Funct. Mater. (China) 46, 06066 (2015).

G. Herzer, IEEE Trans. Magn. 26, 1397 (2002).

I. Hemmati, H.R.M. Hosseini, and A. Kianvash, J. Magn. Magn. Mater. 305, 147 (2006).

G.T. Xia, Y.G. Wang, J. Dai, and Y.D. Dai, J. Alloy. Compd. 690, 281 (2017).

T.H. Noh, M.B. Lee, H.J. Kim, and I.K. Kang, J. Appl. Phys. 67, 5568 (1990).

Y. Liu, Y. Yi, W. Shao, and Y. Shao, J. Magn. Magn. Mater. 330, 119 (2013).

A.H. Taghvaei, H. Shokrollahi, K. Janghorban, and H. Abiri, Mater. Des. 30, 3989 (2009).

Y.B. Kim, D.H. Jang, H.K. Seok, and Y. Kim, Mater. Sci. Eng. A Struct. 449, 389 (2007).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 51472004 and 51272003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Z., Liu, X., Feng, S. et al. Fabrication of an Fe80.5Si7.5B6Nb5Cu Amorphous-Nanocrystalline Powder Core with Outstanding Soft Magnetic Properties. J. Electron. Mater. 47, 1819–1823 (2018). https://doi.org/10.1007/s11664-017-5963-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-017-5963-1