Abstract

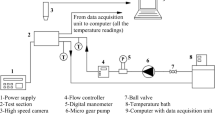

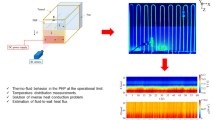

This study presents an experimental investigation of the influence of different heating types on the pumping performance of a bubble pump. A test rig was set up at the Institute of Thermodynamics and Thermal Engineering (ITW), University of Stuttgart. The vertical lift tube is made of copper with an inner diameter of 8 mm and a length of 1.91 m. The working fluid is demineralized water. The test rig offers the possibility to vary the supplied heat flow (0 W − 750 W), the resulting supplied heat flux and the location of the heating. Investigations were carried out using spot heating, partial-length heating and full-length heating. A Coriolis mass flowmeter was successfully implemented which measures the vapor mass flow rate continuously. The improvement of the vapor mass flow rate measurement by using the continuous measurement method compared to a discontinuous one is discussed. Furthermore, the influence of an unstable inlet temperature of the working fluid entering the lift tube on the pumping performance is investigated. The focus of this publication lies on the build-up of the test rig with the measurement setup and the analysis of the pumping performance for the three heating types. The measurement results show a big influence of the heating type on the pumping performance. The lower the relative length of the heating, the higher is the pumping ratio which is defined as the lifted liquid mass flow rate in relation to the generated vapor mass flow rate.

Similar content being viewed by others

Abbreviations

- A:

-

Amperemeter

- d:

-

Downwards

- DAR:

-

Diffusion absorption refrigerator

- u:

-

Upwards

- V:

-

Voltmeter

- A :

-

Cross sectional area (m2)

- b :

-

Pumping ratio (−)

- c p :

-

Specific heat capacity at constant pressure (kJ kg−1 K−1)

- D :

-

Diameter (m)

- g :

-

Gravitational acceleration (m s−2)

- ΔH :

-

Height (m)

- Δh v :

-

Specific enthalpy of evaporation (kJ kg−1)

- L :

-

Length (m)

- \( \dot{M} \) :

-

Mass flow rate (kg s−1)

- P :

-

Power (W)

- Δp :

-

Relative pressure (bar)

- \( \dot{Q} \) :

-

Heat flow (W)

- \( \dot{q} \) :

-

Heat flux (W m−2)

- S :

-

Slip ratio (−)

- S R :

-

Submergence ratio (−)

- t :

-

Time (min)

- \( \dot{V} \) :

-

Volumetric flow rate (m3 h−1)

- w :

-

Velocity (m s−1)

- x :

-

Coordinate in flow direction (m)

- ϑ :

-

Celsius temperature (°C)

- ϑ s :

-

Boiling temperature (°C)

- λ :

-

Thermal conductivity (W m−1 K−1)

- ρ :

-

Density (kg m−3)

- \( \overline{\rho} \) :

-

Mean density over length (kg m−3)

- φ :

-

Relative length of heating (−)

- amb:

-

Ambient

- cartr:

-

Cartridges

- disc:

-

Discontinuous

- el:

-

Electric

- evap:

-

Evaporation

- ext:

-

External

- f:

-

Friction

- FDR:

-

Friction dominant regime

- GDR:

-

Gravity dominant regime

- heat:

-

Supplied heat flow

- HX2:

-

Double-pipe heat exchanger 2

- in:

-

At the inlet

- L:

-

Liquid

- LT:

-

Lift tube

- m:

-

Mean

- mass:

-

Related to the mass

- max:

-

Maximum

- min:

-

Minimum

- out:

-

At the outlet

- part:

-

Partial

- preheat:

-

Preheating

- rel:

-

Relative

- res:

-

Reservoir

- TP:

-

Two-phase

- V:

-

Vapor

- vol:

-

Related to the volume

References

Gartia MR, Vijayan PK, Pilkhwal DS (2006) A generalized flow correlation for two-phase natural circulation loops. Nucl Eng Des 236:1800–1809

Franco A, Filippeschi S (2013) Experimental analysis of Closed Loop Two Phase Thermosyphon (CLTPT) for energy systems. Exp Thermal Fluid Sci 51:302–311

Dometic GmbH (2014) Aktuelles. http://www.dometic.com/de/Europe/Germany/ Aktuelles. Accessed November 2014

Schmid F, Bierling B, Spindler K (2013) Entwicklung einer direkt solarthermisch angetriebenen Diffusions-Absorptionskältemaschine. KI Kälte - Luft - Klimatechnik 49:22–27

Schmid F, Spindler K (2016) Experimental investigation of the auxiliary gas circuit of a diffusion absorption chiller with natural and forced circulation. Int J Refrig 70:84–92

Cattaneo AG (1935) Über die Förderung von Flüssigkeiten mittels der eigenen Dämpfe. Zeitschrift für die gesamte Kälte-Industrie 42:2–52

Delano A (1998) Design Analysis of the Einstein Refrigeration Cycle. Dissertation, Georgia Institute of Technology

Brendel T, Spindler K (2014) Untersuchungen zum Förderverhalten einer Thermosiphonpumpe. Jahrestagung des Deutschen Kälte- und Klimatechnischen Vereins AA.II.1.08

Shihab AS, Morad AMA (2012) Experimental Investigation of Water Vapor-Bubble Pump Characteristics and its Mathematical Model Reconstruction. Eng Tech J 30:1870–1885

Vicatos G, Bennett A (2007) Multiple lift tube pumps boost refrigeration capacity in absorption plants. J Energy South Afr 18:49–57

Chan KW, McCulloch M (2013) Analysis and modelling of water based bubble pump at atmospheric pressure. Int J Refrig 36:1521–1528

Rattner AS, Garimella S (2015) Coupling-fluid heated bubble pump generators: Experiments and model development. Science and Technology for the Built Environment 21:332–347

Verein Deutscher Ingenieure (VDI) - Gesellschaft Verfahrenstechnik und Chemieingenieurwesen (GVC) (2010) VDI Heat Atlas, 2nd edn. Springer, Berlin, New York

Coollaboratory (2016) Coollaboratory Liquid Pro. http://www.coollaboratory.com/product/coollaboratory-liquid-pro. Accessed July 2016

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Bierling, B., Schmid, F. & Spindler, K. Influence of different heating types on the pumping performance of a bubble pump. Heat Mass Transfer 55, 67–79 (2019). https://doi.org/10.1007/s00231-017-2210-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-2210-5