Abstract

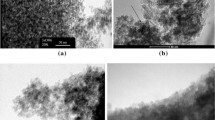

In this study, multi-walled carbon nanotubes (MWCNTs) were developed via the decomposition of acetylene gas over tri-metallic (Fe/Co/Ni) catalyst supported on \(\hbox {CaCO}_{3}\) in a vapor deposition (CVD) reactor. The effects of mass of \(\hbox {CaCO}_{3}\) support, pre-calcination temperature and pre-calcination time on the yield of catalyst were investigated and optimized using \(2^{3}\) factorial experimental design. The catalyst obtained at the optimal conditions was utilized for MWCNTs production using catalytic chemical vapor deposition method (CCVD). The effects of growing time and deposition temperatures on the yield of the MWCNTs were also studied. The as-synthesized catalyst and MWCNTs were characterized using the following analytical techniques: HRSEM, HRTEM, FTIR, TGA/DTA, EDS, XRD, and BET surface area. The results revealed that the optimal experimental conditions to obtain the maximum catalyst yield of 92.04% were: mass of \(\hbox {CaCO}_{3}\) support of 8 g, pre-calcination temperature of 110 \(^{\circ}\hbox {C}\), and pre-calcination time of 8 h. The TGA and BET analysis showed that the catalyst developed at the optimal conditions were thermally stable with a high surface area of 224.68 \(\hbox {m}^{2}/\hbox {g}\) and particle size distribution in the ranges of 0.1–60 nm. The HRSEM and HRSEM micrograph revealed that the produced CNTs were multi-walled carbon nanotubes in nature comprises homogeneous well-aligned woven-like structure. XRD patterns confirmed that the produced MWCNTs were highly graphitized with little structural defects. This present work indicated that MWCNTs of uniform strands and controlled structure can be produced from tri-metallic (Fe/Co/Ni) catalyst supported on \(\hbox {CaCO}_{3}\) through CCVD technique.

Similar content being viewed by others

References

Allaedini, G.; Tasirin, S.M.; Aminayi, P.; Yaakob, Z.; Talib, M.Z.M.: Bulk production of bamboo-shaped multi-walled carbon nanotubes via catalytic decomposition of methane over tri-metallic Ni–Co–Fe catalyst. React. Kinet. Mech. Catal. 116, 385–396 (2015)

Amiri, A.; Maghrebi, M.; Baniadam, M.; Zeinali, H.S.: One-pot, efficient functionalization of multi-walled carbon nanotubes with diamines by microwave method. Appl. Surf. Sci. 257, 10261–10266 (2011)

Iijima, S.: Helical microtubules of graphitic carbon. Nature 354, 56–58 (1991)

Jeong, S.W.; Son, S.Y.; Lee, D.H.: Synthesis of multi-walled carbon nanotubes using Co–Fe–Mo/Al\(_{2}\text{O}_{3}\) catalytic powders in a fluidized bed reactor. Adv. Powder Technol. 21, 93–99 (2010)

Voelskow, K.; Becker, M.J.; Xia, W.; Muhler, M.; Turek, T.: The influence of kinetics, mass transfer and catalyst deactivation on the growth rate of multiwalled carbon nanotubes from ethene on a cobalt-based catalyst. Chem. Eng. J. 244, 68–74 (2014)

Yang, X.; Zou, T.; Shi, C.; Liu, E.; He, C.; Zhao, N.: Effect of carbon nanotube (CNT) content on the properties of in-situ synthesis CNT reinforced Al composites. Mater. Sci. Eng. A660, 11–18 (2016)

Kavecký, S.; Valúchova, J.; Čaplovičová, M.; Heissler, S.; Šajgalík, P.; Janek, M.: Nontronites as catalyst for synthesis of carbon nanotubes by catalytic chemical vapor deposition. Appl. Clay Sci. 114, 170–178 (2015)

Liu, W.W.; Chai, S.P.; Mohamed, A.R.; Hashim, U.: Synthesis and characterization of graphene and carbon nanotubes: a review on the past and recent developments. J. Ind. Eng. Chem. 20, 1171–1185 (2014)

Bahgat, M.; Farghali, A.A.; El Rouby, W.M.A.; Khedr, M.H.: Synthesis and modification of multi-walled carbon nanotubes (MWCNTs) for water treatment applications. J. Anal. Appl. Pyrol. 92, 307–313 (2011)

Chiwaye, N.; Jewell, L.L.; Billing, D.G.; Naidoo, D.; Ncube, M.; Coville, N.J.: In situ powder XRD and Mössbauer study of Fe–Co supported on \(\text{CaCO}_{3}\). Mater. Res. Bull. 56, 98–106 (2014)

Motchelaho, M.A.M.; Xiong, H.; Moyo, M.; Jewell, L.L.; Coville, N.J.: Effect of acid treatment on the surface of multiwalled carbon nanotubes prepared from Fe–Co supported on \(\text{CaCO}_{3}\): correlation with Fischer–Tropsch catalyst activity. J. Mol. Catal. A Chem. 335, 189–198 (2011)

Duan, X.; Wang, D.; Qian, G.; Walmsley, J.C.; Holmen, A.; Chen, D.; Zhou, X.: Fabrication of K-promoted iron/carbon nanotubes composite catalysts for the Fischer–Tropsch synthesis of lower olefins. J. Energy Chem. 0, 1–7 (2016)

Cheng, J.; Zhang, X.; Luo, Z.; Liu, F.; Ye, Y.; Yin, W.; Liu, W.; Han, Y.: Carbon nanotube synthesis and parametric study using \(\text{CaCO}_{3}\) nanocrystals as catalyst support by CVD. Mater. Chem. Phys. 95, 5–11 (2006)

Chen, C.M.; Dai, Y.M.; Huang, J.W.; Jehng, J.M.: Intermetallic catalyst for carbon nanotubes (CNTs) growth by thermal chemical vapor deposition method. Carbon 44, 1808–1820 (2006)

Yeoh, W.M.; Lee, K.Y.; Chai, S.P.; Lee, K.T.; Mohamed, A.: Synthesis of high purity multi-walled carbon nanotubes over Co–Mo/MgO catalyst by the catalytic chemical vapour deposition of methane’. New Carbon Mater. 24, 60041–60044 (2009)

Taleshi, F.: Evaluation of New Processes to Achieve a High Yield of Carbon Nanotubes by CVD Method. Int. Nano Lett. 2, 23–28 (2012)

Mhlanga, S.D.; Mondal, K.C.; Carter, R.; Witcomb, M.J.; Coville, N.J.: The effect of synthesis parameters on the catalytic synthesis of multiwalled carbon nanotubes using Fe–Co/\(\text{CaCO}_{3}\) catalysts. S. Afr. J. Chem. 62, 67–76 (2009)

Schmitt, T.C.; Biris, A.S.; Miller, D.W.; Biris, A.R.; Lupu, D.; Trigwell, S.; Rahman, Z.U.: Analysis of effluent gases during the CCVD growth of multi-wall carbon nanotubes from acetylene. Carbon 44, 2032–2038 (2006)

Magrez, A.; Seo, J.W.; Smajda, R.; Mioni, M.; Forró, L.: Catalytic CVD synthesis of carbon nanotubes: towards high yield and low temperature growth. Materials 3, 4871–4891 (2010)

Li, Z.; Dervishi, E.; Xu, Y.; Ma, X.; Saini, V.; Biris, A.S.; Little, R.; Lupu, D.: Effects of the Fe–Co interaction on the growth of multiwall carbon nanotubes. J. Chem. Phys. 129, 074712–074717 (2008)

Khavarian, M.; Chais, S.P.; Tan, S.H.; Mohamed, A.R.: Effect of different parameters on the morphology of carbon nanotubes structure grown by floating catalyst method. J. Appl. Sci. 11, 2382–2387 (2011)

Kariim, I.; Abdulkareem, AS.; Abubakre, OK.; Mohammed, IA.; Bankole, MT.; Tijani, JO.: Studies on the suitability of alumina as bimetallic catalyst support for MWCNTs growth in a CVD reactor. First International Engineering Conference, School of Engineering and Engineering Technology, Federal University of Technology, Minna, Nigeria, pp. 296–305 (2015)

Allaedini, G.; Aminayi, P.; Tasirin, S.M.: Methane decomposition for carbon nanotube production: optimization of the reaction parameters using response surface methodology. Chem. Eng. Res. Des. 112, 163–174 (2016). (2016)

Hanaei, H.: The interaction effects of synthesis reaction temperature and deposition time on carbon nanotubes (CNTs) yield. Int. J. Mater. Sci. 1, 54–61 (2013)

Maccallini, E.; Tsoufis, T.; Policicchio, A.; La Rosa, S.; Caruso, T.; Chiarello, G.; Colavita, E.; Formoso, V.; Gournis, D.; Agostino, R.G.: A spectro-microscopic investigation of Fe–Co bimetallic catalysts supported on MgO for the production of thin carbon nanotubes. Carbon 48, 3434–3445 (2010)

Mahmoodi, A.; Ghoranneviss, M.M.; Mojtahedzadeh, S.H.; Haji, H.; Eshghabadi, M.: Various temperature effects on the growth of carbon nanotubes (CNTs) by thermal chemical vapor deposition (TCVD) method. Int. J. Phys. Sci. 7(6), 949–952 (2012)

Mhlanga, S.D.; Coville, N.J.: Iron–cobalt catalysts synthesized by a reverse micelle impregnation method for controlled growth of carbon nanotubes. Diam. Relat. Mater. 17, 1489–1493 (2008)

Nair, N.; Kim, W.J.; Braatz, R.D.; Strano, R.D.: Dynamics of suspended single-walled carbon nanotubes in a centrifugal field. Langmuir 24, 1790–1795 (2008)

Al-Rub, R.K.A.; Ashour, A.I.; Tyson, B.M.: On the aspect ratio effect of multi-walled carbon nanotube reinforcements on the mechanical properties of cementitious nanocomposites. Constr. Build. Mater. 35, 647–655 (2012)

Afolabi, A.S.; Abdulkareem, A.S.; Mhlanga, S.D.; Iyuke, S.E.: Synthesis and purification of bimetallic catalysed carbon nanotubes in a horizontal CVD reactor. J. Exp. Nanosci. 6(3), 248–262 (2011)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdulkareem, A.S., Kariim, I., Bankole, M.T. et al. Synthesis and Characterization of Tri-metallic Fe–Co–Ni Catalyst Supported on \(\hbox {CaCO}_{3}\) for Multi-Walled Carbon Nanotubes Growth via Chemical Vapor Deposition Technique. Arab J Sci Eng 42, 4365–4381 (2017). https://doi.org/10.1007/s13369-017-2478-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-017-2478-2