Abstract

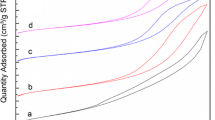

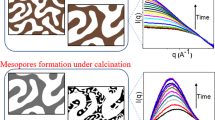

Hierarchical macroporous–mesoporous alumina (HMMA) and hierarchical mesoporous alumina (HMA) monolithic green bodies were fabricated by cold isostatic pressing (CIP) of mesoporous alumina (MA) powder, which was prepared by a quick, facile and very pure synthesis route that involved exploitation of the naturally self-driven aluminum nitride powder hydrolysis. The hierarchically self-assembled, nanocrystalline, yet micron-sized MA powder exhibited a controlled porosity, a fine crystallite size, a relatively large surface area and large pore volumes. The textural characteristics of the MA powder were analyzed, while the effect of the consolidation pressure on the pore size evolution, mechanical and permeability properties of the consolidated HMMA and HMA monoliths were investigated. At the lowest CIP pressures, the HMMA monoliths possessed favorable permeability characteristics with Darcian permeability constants up to 2 × 10−15 m2, also exhibiting a low thermal conductivity (≥0.185 W/mK), sufficient flexural strength (≥6 MPa) with an accessible porosity of ≤65%, a pore volume of ≤0.69 cm3/g and a macropore opening diameter of ≤370 nm at a constant mesopore opening diameter of about 4.5 nm. Increasing the CIP pressure resulted in the shrinkage of the macropores and a consequent suppression of the permeability characteristics; however, the flexural strength of the HMA monolith CIPed at 800 MPa increased to 51 MPa, which is the highest reported strength for a dry-pressed, binderless ceramic green body with an accessible porosity of 42% and a theoretical density of 44.3%.

Similar content being viewed by others

References

Euzen P, Raybaud P, Krokidis X et al (2002) Alumina. In: Schüth F, Sing K, Weitkamp J (eds) Handbook of porous solids. Wiley-VCH, Weinheim, pp 1591–1677

Webster TJ, Hellenmeyer EL, Price RL (2005) Increased osteoblast functions on theta + delta nanofiber alumina. Biomaterials 26:953–960. doi:10.1016/j.biomaterials.2004.03.040

Maquieira Á, Brun EM, Garcés-García M, Puchades R (2012) Aluminum oxide nanoparticles as carriers and adjuvants for eliciting antibodies from non-immunogenic haptens. Anal Chem 84:9340–9348. doi:10.1021/ac3020998

Levin I, Brandon D (1998) Metastable alumina polymorphs: crystal structures and transition sequences. J Am Ceram Soc 81:1995–2012

Iler R (1961) Fibrillar colloidal boehmite; progressive conversion to gamma, theta, and alpha aluminas. J Am Ceram Soc 44:618–624

Deng W, Toepke MW, Shanks BH (2003) Surfactant-assisted synthesis of alumina with hierarchical nanopores. Adv Funct Mater 13:61–65. doi:10.1002/adfm.200390007

Ren TZ, Yuan ZY, Su BL (2004) Microwave-assisted preparation of hierarchical mesoporous-macroporous boehmite AlOOH and γ-Al2O3. Langmuir 20:1531–1534. doi:10.1021/la0361767

Zhang K, Fu Z, Nakayama T, Niihara K (2012) Structural evolution of hierarchically macro/mesoporous Al2O3 monoliths under heat-treatment. Microporous Mesoporous Mater 153:41–46. doi:10.1016/j.micromeso.2011.12.014

Li L-L, Duan W-T, Yuan Q et al (2009) Hierarchical γ-Al2O3 monoliths with highly ordered 2D hexagonal mesopores in macroporous walls. Chem Commun 41:6174–6176. doi:10.1039/b912495k

Tokudome Y, Fujita K, Nakanishi K et al (2007) Synthesis of monolithic Al2O3 with well-defined macropores and mesostructured skeletons via the sol–gel process accompanied by phase separation. Chem Mater 13:3393–3398. doi:10.1021/cm063051p

Passos AR, Pulcinelli SH, Briois V, Santilli CV (2016) High surface area hierarchical porous Al 2 O 3 prepared by the integration of sol–gel transition and phase separation. RSC Adv 6:57217–57226. doi:10.1039/C6RA11477F

Xu G, Li J, Cui H et al (2015) Biotemplated fabrication of porous alumina ceramics with controllable pore size using bioactive yeast as pore-forming agent. Ceram Int 41:7042–7047. doi:10.1016/j.ceramint.2015.02.007

Bian S-W, Zhang Y-L, Li H-L et al (2010) γ-Alumina with hierarchically ordered mesopore/macropore from dual templates. Microporous Mesoporous Mater 131:289–293. doi:10.1016/j.micromeso.2010.01.004

Parlett CMA, Wilson K, Lee AF (2013) Hierarchical porous materials: catalytic applications. Chem Soc Rev Chem Soc Rev 42:3876–3893. doi:10.1039/c2cs35378d

Henry M, Jolivet JP, Livage J (1992) Aqueous chemistry of metal cations: hydrolysis, condensation and complexation. In: Reisfeld R, Jorgensen CK (eds) Chemistry, spectroscopy and applications of sol-gel glasses, Structure and bonding, vol 77. Springer-Verlag, Berlin, Heidelberg, pp 153–206

Kocjan A, Krnel K, Kosmač T (2008) The influence of temperature and time on the AlN powder hydrolysis reaction products. J Eur Ceram Soc 28:1003–1008

Kocjan A, Dakskobler A, KosmacÌŒ T (2012) Evolution of aluminum hydroxides in diluted aqueous aluminum nitride powder suspensions. Cryst Growth Des 12:1299–1307

Kocjan A, Dakskobler A, Krnel K, Kosmač T (2011) The course of the hydrolysis and the reaction kinetics of AlN powder in diluted aqueous suspensions. J Eur Ceram Soc 31:815–823. doi:10.1016/j.jeurceramsoc.2010.12.009

Dakskobler A, Kocjan A, Kosmač T (2011) Porous alumina ceramics prepared by the hydrolysis-assisted solidification method. J Am Ceram Soc 94:1374–1379. doi:10.1111/j.1551-2916.2010.04258.x

Kocjan A, Ambrožič M, Kosmač T (2012) Stereometric analysis of nanostructured boehmite coatings synthesized by aluminum nitride powder hydrolysis. Ceram Int 38:4853–4859. doi:10.1016/j.ceramint.2012.02.075

Kocjan A, Dakskobler A, Kosmac T (2011) Superhydrophobic nanostructured boehmite coatings prepared by AlN powder hydrolysis. Int J Appl Ceram Technol 8:848–853. doi:10.1111/j.1744-7402.2010.02516.x

Jevnikar P, Krnel K, Kocjan A et al (2010) The effect of nano-structured alumina coating on resin-bond strength to zirconia ceramics. Dent Mater 26:688–696. doi:10.1016/j.dental.2010.03.013

Wicklein B, Kocjan A, Salazar-Alvarez G et al (2015) Thermally insulating and fire-retardant lightweight anisotropic foams based on nanocellulose and graphene oxide. Nat Nanotechnol 10:277–283. doi:10.1038/nnano.2014.248

Zhang S, Kocjan A, Lehmann F et al (2010) Influence of contamination on resin bond strength to nano-structured alumina-coated zirconia ceramic. Eur J Oral Sci 118:396–403. doi:10.1111/j.1600-0722.2010.00752.x

Krokidis X, Raybaud P (2001) Theoretical study of the dehydration process of boehmite to γ-alumina. J Phys Chem B 105:5121–5130

Okada K, Nagashima T, Kameshima Y, Yasumori A (2002) Effect of crystallite size on the thermal phase change and porous properties of boehmite. J Colloid Interface Sci 248:111–115. doi:10.1006/jcis.2001.8183

Klug HP, Alexander LE (1954) X-ray diffraction procedures for polycrystalline and amorphous materials, second. Wiley, New York

Logar M, Kocjan A, Dakskobler A (2012) Photocatalytic activity of nanostructured γ-Al2O3/TiO2 composite powder formed via a polyelectrolyte-multilayer-assisted sol–gel reaction. Mater Res Bull 47:12–17. doi:10.1016/j.materresbull.2011.10.017

Li M, Schnablegger H, Mann S (1999) Coupled synthesis and self-assembly of nanoparticles to give structures with controlled organization. Nature 402:393–395. doi:10.1038/46509

Cai W, Yu J, Gu S, Jaroniec M (2010) Facile hydrothermal synthesis of hierarchical boehmite: sulfate-mediated transformation from nanoflakes to hollow microspheres. Cryst Growth Des 10:3977–3982. doi:10.1021/cg100544w

Liu Y, Ma D, Han X et al (2008) Hydrothermal synthesis of microscale boehmite and gamma nanoleaves alumina. Mater Lett 62:1297–1301. doi:10.1016/j.matlet.2007.08.067

Zhang L, Zhu Y-J (2008) Microwave-assisted solvothermal synthesis of AlOOH hierarchically nanostructured microspheres and their transformation to γ-Al2O3 with similar morphologies. J Phys Chem C 112:16764–16768. doi:10.1021/jp805751t

Bowen P, Carry C, Luxembourg D, Hofmann H (2005) Colloidal processing and sintering of nanosized transition aluminas. Powder Technol 157:100–107. doi:10.1016/j.powtec.2005.05.015

Sumirat I, Ando Y, Shimamura S (2006) Theoretical consideration of the effect of porosity on thermal conductivity of porous materials. J Porous Mater 13:439–443. doi:10.1007/s10934-006-8043-0

Yang H-S, Bai G-R, Thompson LJ, Eastman JA (2002) Interfacial thermal resistance in nanocrystalline yttria-stabilized zirconia. Acta Mater 50:2309–2317. doi:10.1016/S1359-6454(02)00057-5

Yu B, Lange F (2001) Colloidal isopressing: a new shape-forming method. Adv Mater 93106:276–280

Romdhane M, Chartier T, Baklouti S et al (2007) A new processing aid for dry-pressing: a copolymer acting as dispersant and binder. J Eur Ceram Soc 27:2687–2695. doi:10.1016/j.jeurceramsoc.2006.11.076

Zysset PK, Guo XE, Hoffler CE et al (1999) Elastic modulus and hardness of cortical and trabecular bone lamellae quantified by nanoindentation. J Biomech 32:1005–1012

Burghard Z, Leineweber A, Van Aken PA et al (2013) Hydrogen-bond reinforced vanadia nanofiber paper of high stiffness. Adv Mater 25:2468–2473. doi:10.1002/adma.201300135

Ohji T, Fukushima M (2012) Macro-porous ceramics: processing and properties. Int Mater Rev 57:115–131. doi:10.1179/1743280411Y.0000000006

Konegger T, Patidar R, Bordia RK (2015) A novel processing approach for free-standing porous non-oxide ceramic supports from polycarbosilane and polysilazane precursors. J Eur Ceram Soc 35:2679–2683. doi:10.1016/j.jeurceramsoc.2015.03.009

Acknowledgements

Slovenian Research Agency is acknowledged for funding the research program Engineering and Bio-ceramics (P2-0087). The authors are grateful to Darko Eterovič for the specimen preparation and mechanical testing.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kocjan, A., Konegger, T. & Dakskobler, A. Hierarchical macroporous–mesoporous γ-alumina monolithic green bodies with high strength. J Mater Sci 52, 11168–11178 (2017). https://doi.org/10.1007/s10853-017-0894-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0894-z