Abstract

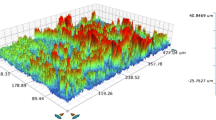

It has been established that nitrogen implantation can modify metals surface properties such as corrosion, wear, friction, etc. Recent studies have shown that nitrogen implantation into titanium and its alloys leads to the formation of titanium nitride, which has interesting biological, chemical, and mechanical properties. In the present investigation, commercially pure biocompatible titanium implanted by nitrogen. Implantation of ions performed at 80 keV and a dose of 2.1 × 1018 ions/cm2 at four different temperatures of 300, 473, 673 and 873 k. Phase and chemical compositions of modified surfaces after implantation obtained using grazing incidence X-ray diffraction technique (GIXRD) and Fourier transform infrared spectrum (FTIR), respectively. The roughness variations before and after ion implantation were observed by atomic force microscopy (AFM). Electrochemical behavior of the samples was investigated in Ringer solution by using electrochemical impedance spectroscopy and polarization tests. Scanning electron microscopy micrographs was used to evaluate the surface morphology of the samples. Variation of the Young’s modulus and hardness of samples were examined using nano-indentation technique before and after ion implantation. Compared to nano-hardness of unimplanted sample, the maximum nano-hardness value of implanted samples is as high as 14.2 GPa, which is at least eight times larger than hardness of the unimplanted sample. The elastic modulus of unimplanted sample was obtained 106 GPa and the maximum elastic modulus value of implanted samples is as high as 178 GPa. Corrosion test results showed that implantation could increase the corrosion resistance of samples, but by increasing the implantation temperature, the corrosion resistance will decrease.

Graphical Abstract

Similar content being viewed by others

References

Rautray TR, Narayanan R, Kwon TY, Kim KH. Surface modification of titanium and titanium alloys by ion implantation. J Biomed Mater Res B Appl Biomater. 2010;93B(2):581–91.

Rautray TR, Narayanan R, Kim KH. Ion implantation of titanium based biomaterials. Prog Mater Sci. 2011;56(8):1137–77.

Torrisi L. Ion implantation and thermal nitridation of biocompatible titanium. Biomed Mater Eng. 1996;6(5):379–88.

Kustas FM, Misra MS, Wei R, Wilbur PJ. High temperature nitrogen implantation of Ti-6Al-4V I: microstructure characterization. Surf Coat Technol. 1992;51(1–3):100–5.

Budzynski P, Youssef AA, Sielanko J. Surface modification of Ti–6Al–4V alloy by nitrogen ion implantation. Wear. 2006;261(11–12):1271–76.

Lee DB, Pohrelyuk I, Yaskiv O, Lee JC. Gas nitriding and subsequent oxidation of Ti-6Al-4V alloys. Nanoscale Res Lett. 2012;7(21):1–5.

Liu YZ, Zu XT, He X, Qiu SY, Cao J, Huang XQ. Improvement of tribological behavior of a Ti–Al–Zr alloy by nitrogen ion implantation. Nucl Instrum Methods Res B. 2006;248(1):42–46.

Ion R, Vasilescu C, Drob P, Vasilescu E, Cimpean A, Drob SI, Gordin DM, Gloriant T. Long-term corrosion performances and cytocompatibility of nitrided Ti and Ti–6Al–4V alloy in severe functional conditions. Mater Corros. 2012;9999(9999):1–12.

Rosca JCM, Vasilescu E, Drob P, Vasilescu C, Drob SI. Corrosion behavior in physiological fluids of surface films formed on titanium alloys. Mater Corros. 2012;63(6):527–33.

Vadiraj A, Kamaraj M, Mudali UK, Kamachi U, Nath AK. Effect of surface modified layers on fretting fatigue damage of biomedical titanium alloys. Mater Sci Technol. 2006;22(9):1119–25.

Zhao J, Garza EG, Lam K, Jones CM. Comparison study of physical vapor-deposited and chemical vapor-deposited titanium nitride thin films using X-ray photoelectron spectroscopy. Appl Surf Sci. 2000;158(3–4):246–51.

Anttila A, Raisanen J, Keinonen J. Diffusion of nitrogen in α-Ti. Appl Phys Lett. 1983;42(6):498–500.

Rauschenbach B. Formation of compounds by high-flux nitrogen ion implantation in titanium. J Mater Sci. 1986;21(2):395–404.

Heide N, Schultze JW. Corrosion stability of TiN prepared by ion implantation and PVD. Nucl Instrum Methods Phys Res B. 1993;80–81:467–71.

Starosvetsky D, Gotman I. Corrosion behavior of titanium nitride coated Ni-Ti shape memory surgical alloy. Biomaterials. 2001;22(13):1853–59.

Huang HH, Hsu CH, Pan SJ, He JL, Chen CC, Lee TL. Corrosion and cell adhesion behavior of TiN-coated and ion-nitrided titanium for dental applications. Appl Surf Sci. 2005;244(1–4):252–56.

Shenhara A, Gotmana I, Radinb S, Ducheyneb P, Gutmanasa EY. Titanium nitride coatings on surgical titanium alloys produced by a powder immersion reaction assisted coating method: residual stresses and fretting behavior. Surf Coat Technol. 2000;126(2–3):210–18.

Kasukabe Y, Ito A, Nagata S, Kishimoto M, Fujino Y, Yamaguchi S, Yamada Y. Epitaxial growth of (001)-oriented titanium nitride thin films by N implantation. J Vac Sci Technol A. 1998;16(2):482–9.

Fukumoto S, Tsubakino H, Terasawa M, Mitamura T, Nakamura K., Okazaki Y. , Corrosion resistance of nitrogen ion implanted titanium alloy for medical implants in physiological saline solution, Conference on Ion Implantation Technology, (2000), 777–80.

Kurtz SR, Gordon RG. Chemical vapor deposition of titanium nitride at low temperatures. Thin Solid Films. 1986;140(2):277–90.

Shieh J, Hon MH. Nanostructure and hardness of titanium aluminum nitride prepared by plasma enhanced chemical vapor deposition. Thin Solid Films. 2001;391(1):101–8.

Satou M, Andoh Y, Ogata K, Suzuki Y, Matsuda K, Fujimoto F. Coating films of titanium nitride prepared by ion and vapor deposition method. Jpn J Appl Phys. 1985;24(2):656–60.

Yazdani A, Soltanieh M, Aghajani H, Rastegari S. A new method for deposition of nano sized titanium nitride on steels. Vacuum. 2011;86(2):131–9.

Weerasinghe VM, Westb DRF, de Damboreneac J. Laser surface nitriding of titanium and a titanium alloy. J Mater Process Tech. 1996;58(1):79–86.

Lal K, Meikap AK, Chattopadhyay SK, Chatterjee SK, Ghosh M, Baba K, Hatada R. Electrical resistivity of titanium nitride thin films prepared by ion beam-assisted deposition. Physica B Condens Matter. 2001;307(1–4):150–7.

Jeyachandran YL, Narayandass SK, Mangalaraj D, Sami Areva, Mielczarski JA. Properties of titanium nitride films prepared by direct current magnetron sputtering. Mater Sci Eng A. 2007;445–446:223–36.

Lausmaa J, Rostlund T, McKellop H. A surface spectroscopic study of nitrogen ion-implanted Ti and Ti-6A1-4V wear against UHMWPE. Surf Interface Anal. 1990;15(5):328–36.

Savaloni H, Modiri F, Hajihosseini H, Shokouhy A. Characteristics of surface nano-structural modifications in nitrogen ion implanted W as a function of temperature. Appl Surf Sci. 2006;252(15):5419–23.

Shokouhy A, Ghoraneviss M, Borghei M, Yari M, Larijani MM, Haji Hosseini SH, Asadpour A. Effect of nitrogen ion implantation on microstructure and improvement of titanium corrosion resistance. J Fusion Energ. 2011;30(2):190–4.

Firouzi-Arani M, Savaloni H, Ghoranneviss M. Dependence of surface nano-structural modifications of Ti implanted by N+ ions on temperature. Appl Surf Sci. 2010;256(14):4502–11.

Liu BX, Zhou X, Li HD. Thermodynamics and growth kinetical consideration of metal-nitride formation by nitrogen implantation. Phys Status Solidi A. 1989;113(1):11–22.

Vigen Karimi M, Sinha SK, Kothari DC, Khanna AK, Tyagi AK. Effect of ion implantation on corrosion resistance and high temperature oxidation resistance of Ti deposited 316 stainless steel. Surf Coat Technol. 2002;158–159:609–14.

Rauschenbach B. Temperature influence during high-fluence nitrogen ion implantation into iron. Nucl Instrum Methods Phys Res B. 1986;15(1–6):756–9.

Xie L, Worzala FJ, Conrad JR, Dodd RA, Sridharan K. Influence of temperature on nitrogen ion implantation of Incoloy alloys 908 and 909. Mater Sci Eng A. 1991;139:179–84.

Goode PD, Baumvol IJR. The influence of ion implantation factors on the surface modification of steels. Nucl Instrum Methods. 1981;189(1):161–8.

Ramous E, Principi G, Giordano L, Lo Russo S, Tosello C. Thermal effect of nitrogen implantation on high carbon steels. Thin Solid Films. 1983;102(2):97–106.

Moncoffre N, Hollinger G, Jaffrezic H, Marest G, Tousset J. Temperature influence during nitrogen implantation into steel. Nucl Instrum Methods Phys Res B. 1985;7–8:177–83.

Lucas S, Terwagne G, Bodart F. Temperature and fluence dependences of nitrogen implantation into aluminum. Nucl Instrum Methods Phys Res B. 1990;50(1–4):401–5.

Knystautas EJ, Singh A, Fiset M, Gujrathi S, Lemay L. Temperature effect on the microhardness of Ti-overlaid 4145 steel implanted with nitrogen. Nucl Instrum Methods Phys Res B. 1987;24–25:554–6.

Bouten PCP, Miedema AR. On the stable compositions in transition metal-nitrogen phase diagrams. J Less Common Met. 1979;65(2):217–28.

Niessen AK, De Boer FR. The enthalpy of formation of solid borides, carbides, nitrides, silicides and phosphides of transition and noble metals. J Less Common Met. 1981;82:75–80.

Wilkes P. Phase stability under irradiation — a review of theory and experiment. J Nucl Mater. 1979;83(1):166–75.

Masakatsu Maeda, Ryozo Oomoto, Masaaki Naka and Toshiya Shibayanagi, "Interfacial reaction between titanium and silicon nitride during solid state diffusion bonding", Trans JWRI. 2001;30(2): 59–65.

Kelly R. Factors determining the compound phases formed by oxygen or nitrogen implantation in metals. J Vac Sci Tech. 1982;21(3):778–89.

Rauschenbach B, Hochmuth K. Synthesis of compounds by high‐fluence nitrogen ion implantation in titanium. Phys Status Solidi A. 1986;94(2):833–7.

Oliver WC, Phar GM. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res. 1992;7(6):1564–83.

Zhou X, Dong HK, Li HD, Liu BX. Reverse sequence of formation of titanium nitrides by nitrogen implantation. J Appl Phys. 1988;63(10):4942–45.

Zhecheva A, Sha W, Malinov S, Long A. Enhancing the microstructure and properties of titanium alloys through nitriding and other surface engineering methods. Surf Coat Technol. 2005;200(7):2192–207.

Mandl S, Gerlach JW, Rauschenbach B. Nitride formation in transition metals during high fluence–high temperature implantation. Surf Coat Technol. 2005;200:584–8.

Kustas FM, Misra MS, Wet R, Wilbur PJ, Knapp JA. High temperature nitrogen implantation of Ti-6AI-4V I: Microstructure characterization. Surf Coat Technol. 1992;51:100–5.

Savaloni H, Khojier K, Torabi S. Influence of N+ ion implantation on the corrosion and nano-structure of Ti samples. Corros Sci. 2010;52:1263–67.

Savaloni H, Motmaen-Dadgar M, Ghoranneviss M, Hantehzadeh MR. Temperature and N+ energy dependence on nano-structural modifications and characteristics of Mo surface. Appl Surf Sci. 2006;253:2915–23.

Firouzi-Arani M, Savaloni H. Surface nanostructural modifications of Ti implanted by N+ ions as a function of energy. Philos Mag. 2011;91(30):3946–60. 21

Hohmuth K, Rauschenbach B. High fluence implantation of nitrogen ions into titanium. Mater Sci Eng. 1985;69:489–99.

Oliver WC, Mc Hargue CJ, Zinkle SJ. Thin film characterization using a mechanical properties microprobe. Thin Solid Films. 1987;153(1–3):185–96.

Shan Z, Sitaraman SK. Elastic–plastic characterization of thin films using nano-indentation technique. Thin Solid Films. 2003;437(1–2):176–81.

Page TF, Hainsworth SV. Using nano-indentation techniques for the characterization of coated systems: a critique. Surf Coat Technol. 1993;61(1–3):201–8.

GilJunga Y, Lawn BR, Martyniuk M, Huang H, Hu XZ. Evaluation of elastic modulus and hardness of thin films by nano-indentation. J Mater Res. 2004;19(10):3076–80.

William D. Nix, Elastic and plastic properties of thin films on substrates: nano-indentation techniques. Mater Sci Eng A. 1997;234–236:37–44.

Bourcier RJ, Follstaedt DM, Dugger MT, Myers SM. Mechanical characterization of several ion-implanted alloys: nano-indentation testing, wear testing and finite element modeling. Nucl Instrum Methods Phys Res B. 1991;59–60(2):905–8.

Grauman JS. Titanium-properties and application for the chemical process industry, Encyclopedia of Chemical Processing and Design. 58. New York, NY: Marcel Dekker, Inc; 1997. pp. 123–46.

Martin KJ, Madan A, Hoffman D, Ji J, Barnett SA. Mechanical properties and thermal stability of TiN/TiB2 nanolayered thin films. J Vacuum Sci Technol A. 2005;23:90–98.

Ma CH, Huang JH, Chen H. Nanohardness of nanocrystalline TiN thin films. Surf Coat Tech. 2006;200:3868–75.

Mante FK, Baran GR, Lucas B. Nano-indentation studies of titanium single crystals. Biomaterials. 1999;20:1051–55.

Shakoori Oskooie M, Sadeghpour Motlagh M, Aghajani H. Surface properties and mechanism of corrosion resistance enhancement in a high temperature nitrogen ion implanted medical grade Ti. Surf Coat Tech. 2016;291:356–64.

Mondal K, Murty BS, Chatterjee UK. Electrochemical behavior of amorphous and nanoquasi-crystalline Zr–Pd and Zr–Pt alloys in different environments. Corros Sci. 2005;47:2619–35.

Acknowledgements

We wish to express our thanks to Majed Malek for carrying out the implantations.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Aghajani, H., Motlagh, M.S. Effect of temperature on surface characteristics of nitrogen ion implanted biocompatible titanium. J Mater Sci: Mater Med 28, 29 (2017). https://doi.org/10.1007/s10856-016-5843-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-016-5843-x