Abstract

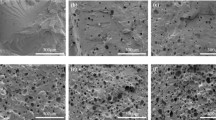

Chitin nanofibers extracted from crab shell were used to reinforce polylactic acid (PLA) by extrusion molding. The dispersion problem of nanofibers in PLA matrix was solved by three pretreatment methods, including water pretreatment, polyethylene glycol (PEG) pretreatment, and polyethylene oxide (PEO) pretreatment. The results demonstrated that chitin nanofibers were distributed uniformly on the fracture surface of the PLA matrix with three different pretreatment methods. However, the aspect ratio of nanofibers with was reduced with the PEG and PEO pretreatment methods. Therefore, the bending modulus (MOE), bending strength (MOR) and impact toughness of the chitin nanofibers/PLA composites prepared by the water pretreatment method were much higher than those of the composites prepared by the PEG and the PEO pretreatment method. Furthermore, the reinforcing effect with the PEG method is slightly better than that with the PEO method. Although it was found that both PEG and PEO were good interfacial compatibilizers for nanofibers and PLA, the reinforcing effect of the composites prepared by PEG and PEO pretreat methods was suppressed due to the decrease of the aspect ratio for chitin nanofibers.

Similar content being viewed by others

References

Angles MN, Dufresne A (2001) Plasticized starch/tunicin whiskers nanocomposite materials 2. Mechanical behavior. Macromolecules 34:2921–2931

Auras RA, Harte B, Selke S, Hernandes R (2003) Mechanical, physical and barrier properties of poly (lactide) films. J Plast Film Sheet 19:123–135

Azouz K, Ramires BE, Fonteyne CWV, Kissi DN, Dufresne EA (2012) Simple method for the melt extrusion of a cellulose nanocrystal reinforced hydrophobic polymer. ACS Macro Lett 1:236–240

Bhardwaj R, Mohanty AK, Drzal LT, Pourboghrast F, Misra M (2006) Renewable resource-based green composites from recycled cellulose fiber and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) bioplastic. Biomacromolecules 7:2044–2051

Bondeson D, Oksman K (2007) Dispersion and characteristics of surfactant modified cellulose whiskers nanocomposites. Compos Interfaces 14:617–630

Brown EE, Laborie MPG (2007) Bioengineering bacterial cellulose/poly(ethylene oxide) nanocomposites. Biomacromolecules 8:3074–3081

Chen CC, Li DG, Hu QQ, Wang R (2014) Properties of polymethyl methacrylate-based nanocomposites: reinforced with ultra-long chitin nanofiber extracted from crab shells. Mater Des 56:1049–1056

Dhar P, Tarafder D, Kumar A, Katiyar V (2016) Thermally recyclable polylactic acid/cellulose nanocrystal films through reactive extrusion process. Polymer 87:268–282

Frone AN, Berlioz S, Chailan JF, Panaitescu DM (2013) Morphology and thermal properties of PLA-cellulose nanofibers composites. Carbohydr Polym 91:377–384

Gopalan NK, Dufresne A (2003) Crab shell chitin whisker reinforced natural rubber nanocomposites. 1. Processing and swelling behavior. Biomacromolecules 4:657–665

Herrera N, Mathew AP, Oksman K (2015) Plasticized polylactic acid/cellulose nanocomposites prepared using melt-extrusion and liquid feeding: mechanical, thermal and optical properties. Compos Sci Technol 106:149–155

Ifuku S, Nogi M, Abe K, Yoshioka M, Morimoto M, Saimoto H (2009) Preparation of chitin nanofibers with a uniform width as α-chitin from crab shells. Biomacromolecules 10:1584–1588

Ifuku S, Nogi M, Abe K, Yoshioka M, Morimoto M, Saimoto H (2011) Simple preparation method of chitin nanofibers with a uniform width of 10–20 nm from prawn shell under neutral conditions. Carbohydr Polym 84:762–764

Indira KN, Jyotishkumar P, Thomas S (2014) Viscoelastic behaviour of untreated and chemically treated banana fiber/PF composites. Fiber Polym 15:91–100

Jonoobi M, Harun J, Mathew AP, Oksman K (2010) Mechanical properties of cellulose nanofiber (CNF) reinforced polylactic acid (PLA) prepared by twin screw extrusion. Compos Sci Technol 70:1742–1747

Kowalczyk M, Piorkowska E, Kulpinski P, Pracella M (2011) Mechanical and thermal properties of PLA composites with cellulose nanofibers and standard size fibers. Compos A 42:1509–1514

Lee KY, Aitomäki Y, Berglund LA, Oksman K, Bismarck A (2014) On the use of nanocellulose as reinforcement in polymer matrix composites. Compos Sci Technol 105:15–27

Li DS, Liu ZY, AlHaik M, Tehrani M, Murray F, Tannenbaum R, Garmestani H (2010) Magnetic alignment of cellulose nanowhiskers in an all-cellulose composite. Polym Bull 65:635–642

Li ZG, Zhou XD, Pei CH (2011) Effect of sisal fiber surface treatment on properties of sisal fiber reinforced polylactide composites. Int J Polym Sci 2011(803428):1–7

Li JJ, Song ZQ, Li DG, Shang SB, Guo Y (2014) Cotton cellulose nanofiber-reinforced high density polyethylene composites prepared with two different pretreatment methods. Ind Crops Prod 59:318–328

López-Suevos F, Eyholzer C, Bordeanu N, Richter K (2010) DMA analysis and wood bonding of PVAc latex reinforced with cellulose nanofibrils. Cellulose 17:387–398

Lu J, Wang T, Drzal LT (2008) Preparation and properties of microfibrillated cellulose polyvinyl alcohol composite materials. Compos A 39:738–746

Montazeri A, Montazeri N (2011) Viscoelastic and mechanical properties of multiwalled carbon nanotube/epoxy composites with different nanotube content. Mater Des 32:2301–2307

Nair KG, Dufresne A (2003) Crab shell whisker reinforced natural rubber nanocomposites. 1. Processing and swelling behavior. Biomacromolecules 4:657–665

Nakagaito AN, Yano H (2008) The effect of fiber content on the mechanical and thermal expansion properties of biocomposites based on microfibrillated cellulose. Cellulose 15:555–559

Nakagaito AN, Fujimura A, Sakai T, Hama Y, Yano H (2009) Production of microfibrillated cellulose (MFC)-reinforced polylactic acid (PLA) nanocomposites from sheets obtained by a papermaking-like process. Compos Sci Technol 69:1293–1297

Nakagaito AN, Yamada K, Ifuku S, Morimoto M, Saimoto H (2013) Fabrication of chitin nanofiber-reinforced polylactic acid nanocomposites by an environmentally friendly process. J Biobased Mater Bio 7:152–156

Pothen LA, Thomas S (2003) Polarity parameters and dynamic mechanical behavior of chemically modified banana fiber reinforced polymer composites. Compos Sci Technol 63:1231–1240

Stark NM, Rowlands E (2003) Effects of wood fiber characteristics on mechanical properties of wood/polypropylene composites. Wood Fiber Sci 35:167–174

Suryanegara L, Nakagaito AN, Yano H (2009) The effect of crystallization of PLA on the thermal and mechanical properties of microfibrillated cellulose-reinforced PLA composites. Compos Sci Technol 69:1187–1192

Suzuki K, Okumura H, Kitagawa K, Sato S, Nakagaito AN, Yano H (2013) Development of continuous process enabling nanofibrillation of pulp and melt compounding. Cellulose 20:201–210

Vincenta JFV, Wegst UGK (2004) Design and mechanical properties of insect cuticle. Arthropod Struct Dev 33:187–199

Wang X, Qu P, Zhang LP (2014) Thermal and structure properties of biobased cellulose nanowhiskers/poly (lactic acid) nanocomposites. Fiber Polym 15:302–306

Zeng JB, He YS, Li SL, Wang YZ (2011) Chitin whiskers: an overview. Biomacromolecules 13:1–11

Acknowledgments

This work is financially supported by Ph.D. Start-up Fund of Northwest A&F University (Z109021613).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, J., Gao, Y., Zhao, J. et al. Homogeneous dispersion of chitin nanofibers in polylactic acid with different pretreatment methods. Cellulose 24, 1705–1715 (2017). https://doi.org/10.1007/s10570-017-1216-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1216-y