Abstract

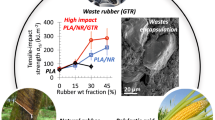

The basis of this work is an investigation of multicomponent systems containing a reactive polyurethane–urea matrix, recycled rubber filler, and porosity. Rubber crumb with varying particle sizes obtained from used car tyres was used as the filler. As a matrix, water-curable isocyanate pre-polymer was used. Porosity was caused by the inability of the matrix to fully fill space between rubber particles, combined with foaming from matrix curing. We report on dependences of PUU/rubber system mechanical properties on the composition and structural parameters. Mechanical property values were obtained via tensile loading of prepared rectangular slabs. We found that mechanical behaviour exhibits strong correlation with a structural parameter called interspace filling, which expresses how much the matrix fills space between filler particles. Interspace filling is dependent on the degree of porosity and the volume fraction of the PUU matrix in a hypothetical nonporous material. Therefore, this work offers a simple characterization of complex materials, of which the studied porous composite is an example. Our results could contribute to the development of applications for large volumes of recycled rubber in materials used in rapid repair of roads and pavements.

Similar content being viewed by others

Abbreviations

- E :

-

Elastic modulus (tensile) (MPa)

- m :

-

Mass (g)

- n :

-

Porosity (%)

- n p :

-

Interspace filling (%)

- T g :

-

Glass transition temperature (°C)

- v :

-

Volume fraction (dimensionless)

- v rubber :

-

Volume fraction of rubber in composite (dimensionless)

- v i :

-

Volume fraction of the ith component of the theoretical nonporous composite (dimensionless)

- v n :

-

Polyurethane–urea volume fraction in theoretical nonporous composite (dimensionless)

- v p :

-

Polyurethane–urea volume fraction in porous composite (dimensionless)

- ρ :

-

Density of composite (g cm−3, kg m−3)

- ρ t :

-

Density of theoretical nonporous composite (g cm−3)

- ρ i :

-

Density of the ith component of the composite (g cm−3)

- σ :

-

Ultimate tensile strength (MPa, kPa)

References

Baatz G (1997) Canadian Patent No. 2,179,145. Canadian Intellectual Patent Office

Bower DK, Hicks S, Terry M, Peeler C, Galecki R, Tutumluer E (2011) International Patent No. 2,011,084,274. World Intellectual Property Organization

Bower DK, Hicks S, Terry M, Peeler CT (2015) Canadian Patent No. 2,784,986. Canadian Intellectual Patent Office

Cachaço AG, Afonso AD, Pinto M (2013) New applications for foam composites of polyurethane and recycled rubber. J Appl Polym Sci 129:2873–2881. doi:10.1002/app.38962

Cialone AM, Waznys P, Grubb M (2011) International Patent No. 3,011,153,399. World Intellectual Property Organization

Cong P, Xun P, Xing M, Chen S (2013) Investigation of asphalt binder containing various crumb rubbers and asphalts. Constr Build Mater 40:632–641. doi:10.1016/j.conbuildmat.2012.11.063

Danch A, Sułkowski WW, Moczyński M, Radoń A, Stelzer F, Jurga S (2004) Structural relaxation and morphology of rubber–urethane composites. J Appl Polym Sci 94:1186–1193. doi:10.1002/app.21027

Danch A, Ilisch S, Sułkowski WW, Moczyński M, Radoń A, Radusch H-J (2005) DMTA study of the urethane network in rubber waste–urethane composites. J Therm Anal Calorim 79(3):623–630

Garcia PS, de Sousa FDB, de Lima JA, Cruz SA, Scuracchio (2015) Devulcanization of ground tire rubber: physical and chemical changes after different microwave exposure times. Express Polym Lett 9:1015–1026. doi:10.3144/expresspolymlett.2015.91

Hicks S, Bower DK, Handlos WG, Kaul J, Arnott BT (2011) International Patent No. 2,010,149,737. World Intellectual Property Organization

Hughes AH, Pennington S (2004) Bonding of rubber particles. European Patent No. 1,400,561. European Patent Office

Johnston J, Zielinski S (2014) International Patent No. 2,014,031,568. World Intellectual Property Organization

Karger-Kocsis J, Felhös D, Xu D (2010) Mechanical and tribological properties of rubber blends composed of HNBR and in situ produced polyurethane. Wear 268:464–472. doi:10.1016/j.wear.2009.08.037

Karger-Kocsis J, Meszaros L, Barany T (2013) Ground tyre rubber (GTR) in thermoplastics, thermosets, and rubbers. J Mater Sci 48:1–38. doi:10.1007/s10853-012-6564-2

Kim JK (1997) Experimental and theoretical studies on crumb rubber/polyurethane blend system. Korea Polym J 5(4):241–247

Maderuelo-Sanz R, Barrigon Morrilas JM, Martin-Castizo M, Escobar VG, Gozalo GR (2013) Acoustical performance of porous absorber made from recycled rubber and polyurethane resin. Latin Am J Solids Struct 10(3):585–600

Piszczyk Ł, Hejna A, Danowska M, Strankowski M, Formela K (2015a) Polyurethane/ground tire rubber composite foams based on polyglycerol: processing, mechanical and thermal properties. J Reinf Plast Compos 34:708–717. doi:10.1177/0731684415579089

Piszczyk Ł, Hejna A, Danowska M, Strankowski M, Formela K (2015b) Effect of ground tire rubber on structural, mechanical and thermal properties of flexible polyurethane foams. Iran Polym J 24:75–84. doi:10.1007/s13726-014-0301-4

Piszczyk Ł, Hejna A, Formela K, Danowska M, Strankowski M (2015c) Rigid polyurethane foams modified with ground tire rubber—mechanical, morphological and thermal studies. Cell Polym 34(2):45–62

Potter GD, Shimizu F (1995) International Patent No. 1,995,025,076. World Intellectual Property Organization

Rodriguez-Alloza AM, Gallego J, Perez I (2013) Study of the effect of four warm mix asphalt additives on bitumen modified with 15% crumb rubber. Constr Build Mater 43:300–308. doi:10.1016/j.conbuildmat.2012.11.063

Sułkowski WW, Danch A, Moczyński M, Radoń A, Sulkowska A, Borek J (2004) Thermogravimetric study of rubber waste–polyurethane composites. J Therm Anal Calorim 78:905–921. doi:10.1007/s10973-005-0457-0

Sułkowski WW, Bartecka G, Sulkowska A, Maślanka S, Borek J, Moczyński M (2012) Thermogravimetric analysis of composites obtained from polyurethane and rubber waste. Mol Cryst Liq Cryst 556:39–51. doi:10.1080/15421406.2012.635907

Zhang X, Lu C, Liang M (2009) Properties of natural rubber vulcanizates containing mechanochemically devulcanized ground tire rubber. J Polym Res 16:411–419. doi:10.1007/s10965-008-9243-x

Zhang X, Lu Z, Tian D, Li H, Lu C (2012) Mechanochemical devulcanization of ground tire rubber and its application in acoustic absorbent polyurethane foamed composites. J Appl Polym Sci 127:4006–4014. doi:10.1002/app.37721

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

This work was financially supported by the Project FCH-S-16-3864.

Rights and permissions

About this article

Cite this article

Černý, M., Jančář, J. Composites based on polyurethane–urea and ground rubber from car tyres: relation between structure and properties. Chem. Pap. 71, 1119–1127 (2017). https://doi.org/10.1007/s11696-016-0060-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-016-0060-0