Abstract

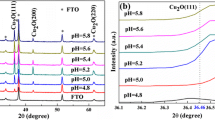

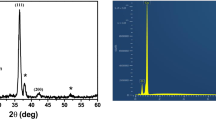

In this work, the effect of the applied cathodic potential on properties of electrodeposited p-type Cu2O thin films was investigated. Electrochemical deposition was carried out on indium tin oxide (ITO) substrate from alkaline Cu(II) lactate-based solution at different cathodic potentials (− 0.60 to − 0.80 V vs. Ag/AgCl) without subsequent annealing. It was shown that changing the electrodeposition applied potential could tune both the phase structure and band gap energy of the Cu2O thin films. The morphological, optical, and structural characterizations of the deposits were carried out using field-emission scanning electron microscopy (FESEM), X-ray diffraction (XRD) and UV-VIS spectroscopy, respectively. FESEM observations of the as-prepared deposits revealed uniform, rough and desert rose-like crystallites composed of square or triangular pyramidal and truncated polyhedral morphologies. The XRD investigation showed that the films were crystalline and revealed the presence of two other sub-stoichiometric copper oxide phases (Cu4O3 and Cu64O), depending on the applied potential. The crystallite size, evaluated using the Scherer formula, varied tightly with the cathode potential and increased in the − 0.65 to − 0.75 V potential range, indicating that the films are of better crystallization. The optical band gaps, deduced from experimental Tauc plots, were found to be 2.33, 1.98, 2.25, 2.27 and 2.50 eV for thin films deposited at − 0.60, − 0.65, − 0.70, − 0.75 and − 0.8 V vs Ag/AgCl, respectively. A mechanism of the phase formation is proposed and discussed.

Similar content being viewed by others

References

W. Ismail, N.M. El-Shafai, A. El-Shaer, and M. Abdelfatah, Mater. Sci. Semicond. Process. 120, 105335 (2020).

Y. Yang, M. Pritzker, and Y. Li, Thin Solid Films 676, 42 (2019).

Y. Qu, J. Qian, J. Liu, L. Yao, L. Zhao, X. Song, P. Zhang, and L. Gao, J. Electrochem. Soc. 166, H452 (2019).

R. Akbari, G. Godeau, M. Mohammadizadeh, F. Guittard, and T. Darmanin, Appl. Surf. Sci. 503, 144094 (2020).

W. Zhang, C. Xu, Y. Hu, S. Yang, L. Ma, L. Wang, P. Zhao, C. Wang, J. Ma, and Z. Jin, Nano Energy 73, 104796 (2020).

V.-H. Nguyen, B.-S. Nguyen, Z. Jin, M. Shokouhimehr, H.W. Jang, C. Hu, P. Singh, P. Raizada, W. Peng, and S.S. Lam, Chem. Eng. J. 402, 126184 (2020).

W. Zhang, Y. Hu, L. Ma, G. Zhu, Y. Wang, X. Xue, R. Chen, S. Yang, and Z. Jin, Adv. Sci. 5, 1700275 (2018).

T. Özdal, and H. Kavak, Superlattice. Microst. 146, 106679 (2020).

M.A. Hossain, R. Al-Gaashani, H. Hamoudi, M.J. Al Marri, I.A. Hussein, A. Belaidi, B.A. Merzougui, F.H. Alharbi, and N. Tabet, Mater. Sci. Semicond. Process. 63, 203 (2017).

A.A. Hssi, L. Atourki, N. Labchir, K. Abouabassi, M. Ouafi, H. Mouhib, A. Ihlal, A. Elfanaoui, S. Benmokhtar, and K. Bouabid, Mater. Today: Proc. 22, 89 (2020).

D.S. Zimbovskii, and B.R. Churagulov, Inorg. Mater. 54, 660 (2018).

S. Choudhary, J. V. N. Sarma, and S. Gangopadhyay, Growth and characterization of single phase Cu2O by thermal oxidation of thin copper films, in (ETMN, Baroda, India, 1724 020116 (2016).

T. Ikenoue, T. Kawai, R. Wakashima, M. Miyake, and T. Hirato, Appl. Phys. Express 12, 055509 (2019).

M.A. Badillo-Ávila, R. Castanedo-Pérez, G. Torres-Delgado, J. Márquez-Marín, and O. Zelaya-Ángel, Mater. Sci. Semicond. Process. 74, 203 (2018).

L. Yuan-Gee, J.-R. Wang, M.-J. Chuang, D.-W. Chen, and K.-H. Hou, Int. J. Electrochem. Sci. 12, 507 (2017).

X. Yu, X. Tang, J. Li, J. Zhang, S. Kou, J. Zhao, and B. Yao, J. Electrochem. Soc. 164, D999 (2017).

M.H. Tran, J.Y. Cho, S. Sinha, M.G. Gang, and J. Heo, Thin Solid Films 661, 132 (2018).

T.D. Golden, M.G. Shumsky, Y. Zhou, R.A. VanderWerf, R.A. Van Leeuwen, and J.A. Switzer, Chem. Mater. 8, 2499 (1996).

M. Abdelfatah, W. Ismail, and A. El-Shaer, Mater. Sci. Semicond. Process. 81, 44 (2018).

M.M. Moharam, E.M. Elsayed, J.C. Nino, R.M. Abou-Shahba, and M.M. Rashad, Thin Solid Films 616, 760 (2016).

X. Jiang, M. Zhang, S. Shi, G. He, X. Song, and Z. Sun, J. Electrochem. Soc. 161, D640 (2014).

S. Laidoudi, A.Y. Bioud, A. Azizi, G. Schmerber, J. Bartringer, S. Barre, and A. Dinia, Semicond. Sci. Tech. 28, 115005 (2013).

K.D. Singh, S.C. Jain, T.D. Sakore, and A.B. Biswas, Z. Kristallogr. 141, 473 (1975).

J. Lee, and Y. Tak, Electrochem. Solid-State Lett. 2, 559 (1999).

S. Bijani, R. Schrebler, E.A. Dalchiele, M. Gabas, L. Martínez, and J.R. Ramos-Barrado, J. Phys. Chem. C 115, 21373 (2011).

L.I. Bendavid, and E.A. Carter, J. Phys. Chem. B 117, 15750 (2013).

B. D. Cullity and S. R. Stock, Elements of X-Ray Diffraction, 3rd ed (Pearson Education Limited, UK, 2014, p. 104).

M.A. Awad, and N.M.A. Hadia, Optik 142, 334 (2017).

M.S. Alqahtani, N.M.A. Hadia, and S.H. Mohamed, Optik 173, 101 (2018).

S. Lee, D.H. Kim, and T.W. Kim, J. Sol-Gel Sci. Technol. 67, 105 (2013).

Y. Gu, X. Su, Y. Du, and C. Wang, Appl. Surf. Sci. 256, 5862 (2010).

S. Rühle, H.N. Barad, Y. Bouhadana, D.A. Keller, A. Ginsburg, K. Shimanovich, K. Majhi, R. Lovrincic, A.Y. Anderson, and A. Zaban, Phys. Chem. Chem. Phys. 16, 7066 (2014).

Y. Zhou, J. Zhao, Y. Liu, R.J.H. Ng, and J.K.W. Yang, Mater. Sci. Semicond. Process. 121, 105444 (2021).

M. Benaicha, M. Hamla, and S. Derbal, Int. J. Electrochem. Sci. 11, 4909 (2016).

M. Fox, Optical Properties of Solids, 2nd ed., (N.Y.: Oxford University Press, 2010).

N.F. Mott, and E.A. Davis, Electronic Processes in Non-Crystalline Materials, 2nd ed., (Oxford: Clarendon Press, 2012).

S. Adachi, Optical Properties of Crystalline and Amorphous Semiconductors (US, Boston, MA: Springer, 1999).

D.S. Murali, and A. Subrahmanyam, J. Phys. D: Appl. Phys. 49, 375102 (2016).

J.P. Zhang, L.D. Zhang, L.Q. Zhu, Y. Zhang, M. Liu, and X.J. Wang, J. Appl. Phys. 102, 114903 (2007).

R. Nathawat, A.K. Kumawat, S.S. Rathore, A.K. Mukhopadhyay, and K. Kabra, J. Nano- Electron. Phys. 13, 01030 (2021).

P.M. Diehm, P. Agoston, and K. Albe, ChemPhysChem 13, 2443 (2012).

Acknowledgments

The authors wish to acknowledge the financial support provided by the Algerian Ministry of Higher Education and Scientific Research through Project PRFU (code: A16N01UN190120190001).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Derbal, S., Benaicha, M. Insights on the Effect of Applied Potential on the Properties of Electrodeposited p-Type Cuprous Oxide (Cu2O) Thin Films. J. Electron. Mater. 50, 5134–5140 (2021). https://doi.org/10.1007/s11664-021-09057-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-021-09057-6