Abstract

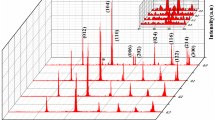

Densified Ba1−xLaxSnO3 (BLSO) ceramics were synthesized at relatively lower sintering temperature by a conventional solid state reaction route. X-ray diffraction (XRD) analysis using the Reitveld refinement technique inferred cubic (space group Pm–3m) average crystalline structure. The effect of La-substitution on variations of lattice parameters could be attributed to two competing factors, viz. ionic radii of the dopant and partial reduction of Sn4+ into Sn2+. XRD data indicate local symmetry reduction from cubic to orthorhombic (Pbnm), evident from the observed splitting in {211}p and {310}p peaks of pseudo cubic structure, as well as corresponding super reflections. The synthesized ceramics were highly porous with percentage densification in the range (60–70)% due to the relatively low sintering temperature used. Densification was improved using 2 wt.% Bi2O3 as a sintering aid, which resulted in highly dense ceramics with relative density ≈ 95%. Sintering temperature reduction of ≈ 300°C was also achieved relative to that required in normal solid state synthesis. This is very important to reduce defects and inhibit uneven grain growth. Microstructure and elemental analysis probed through scanning electron microscopy and energy-dispersive x-ray spectroscopy revealed that Bi replaces lanthanum and that liquid phase sintering is mainly responsible for the high densification using the sintering aid. The structural indicators of symmetry reduction were corroborated by experimentally observed Raman modes in an otherwise symmetry-forbidden cubic phase. The local symmetry reduction is attributed mainly to octahedral tilts corresponding to orthorhombic symmetry.

Similar content being viewed by others

References

P.T. Moseley, D.E. Williams, J.O.W. Norris, and B.C. Tofield, Sens. Actuators 14, 79 (1988).

Y. Shimizu, M. Shimabukaro, H. Arai, and T. Seiyama, J. Electrochem. Soc. 136, 1206 (1989).

U. Lumpe, J. Gerblinger, and H. Meixner, Sens. Actuators, B 24–25, 657 (1995).

U. Lumpe, J. Gerblinger, and H. Meixner, Sens. Actuators, B 26–27, 97 (1995).

I. Kocemba, M.W. Jedrzejewska, A. Szychowska, J. Rynkowski, and M. Gowka, Sens. Actuators, B 121, 401 (2007).

P.K. Bajpai, K. Ratre, M. Pastor, and T.P. Sinha, Bull. Mater. Sci. 26, 461 (2003).

M. Licheron, G. Jouan, and E. Husson, J. Eur. Ceram. Soc. 17, 1453 (1995).

T.R.N. Kutty and R. Vivekanandan, Mater. Res. Bull. 22, 1457 (1987).

C.P. Udawatte, M. Kakihana, and M. Yoshimura, Solid State Ion. 108, 23 (1998).

Y.J. Song and S. Kim, J. Ind. Eng. Chem. 7, 183 (2001).

A.J. Smith and A.J.E. Welch, Struct. Acta Crystallogr. 13, 653 (1960).

E.H. Mountstevens, J.P. Attfeld, and S.A.T. Redfern, J. Phys. Condens. Matter 15, 8315 (2003).

G. Larramona, C. Gutierrez, I. Pereira, M.R. Nunes, and F.M.A. Da Costa, J. Chem. Soc., Faraday Trans. 85, 907 (1989).

H. Mizoguchi, P.M. Woodward, C.H. Park, and H. Keszler, J. Am. Chem. Soc. 126, 9796 (2004).

M. Enhessari and A. Salehabadi, Progresses in Chemical Sensors, ed. W. Wang (London: Intech Open Pub, 2016), pp. 59–92.

R.A. Bucur, A.I. Bucura, S. Novaconi, and I. Nicoara, J. Alloys Compd. 542, 142 (2012).

A. Roy, P. Selvaraj, P.S. Devi, and S. Sundaram, ACS Sustain. Chem. Eng. 6, 3299 (2018).

D.O. Scanlon, Phys. Rev. B 87, 161201 (2013).

S.M. Xing, C. Shan, K. Jiang, J.J. Zhu, Y.W. Li, Z.G. Hu, and J.H. Chu, J. Appl. Phys. 117, 103107 (2015).

F. Huang, D. Chen, X.L. Zhang, R.A. Caruso, and Y.B. Cheng, Adv. Funct. Mater. 20, 1301 (2010).

H.J. Kim, U. Kim, T.H. Kim, J. Kim, H.M. Kim, B.G. Jeon, W.J. Lee, H.S. Mun, K.T. Hong, J. Yu, K. Char, and K.H. Kim, Phys. Rev. B 86, 165205 (2012).

D.T. Anh and N.T. Thanh, Univ. J. Phys. Appl. 11, 235 (2017).

S. Moshtaghi, S. Ajabshir, and M.S. Niasari, J. Mater. Sci. Mater. Electron. 27, 834 (2016).

S. Tao, F. Gao, X. Liu, and O.T. Sùrensen, Sens. Actuators, B 71, 223 (2000).

J. John,V.P.M. Pillai, A.R. Thomas, R. Philip, J. Joseph, S. Muthunatesan,V. Ragavendran, and R. Prabhu, in IOP Conference Proceedings (2017), p. 012007

S. Upadhyay, Bull. Mater. Sci. 36, 1019 (2013).

U. Kumar, M.J. Ansaree, and S. Upadhyay, Process. Appl. Ceram. 1, 177 (2017).

A.M. Azad and N.C. Hon, J Alloys Compd. 270, 95 (1998).

M.G. Smith, J.B. Goodenough, A. Manthiram, R.D. Taylor, W. Peng, and C.W. Kimball, J. Solid State Chem. 98, 181 (1992).

M. Bao, W.D. Lee, and P. Zhu, J. Mater. Sci. 28, 6617 (1993).

S. Upadhayay, O. Prakash, and D. Kumar, J. Mater. Sci. 16, 1330 (1997).

J.C. Farfan, J.A. Rodriguez, F. Fajardo, E. Vera Lopez, D.A.L. Tellez, and J.R. Rojas, Phys. B 404, 2720 (2009).

C. Huang, X. Wang, Q. Shi, X. Liu, Y. Zhang, F. Huang, and T. Zhang, Inorg. Chem. 54, 4002 (2015).

D.W. Kim, S.S. Shin, S. Lee, I.S. Cho, D.H. Kim, C.W. Lee, H.S. Jung, and K.S. Hong, Chemsuschem 6, 449 (2013).

C. Doroftei, P.D. Popa, and F. Iacomi, Sens. Actuators, A 173, 24 (2012).

J. Creda, J. Arbil, R. Diaz, G. Dezannweau, and J.R. Morante, Mater. Lett. 56, 131 (2002).

R. Nakagauchi and H. Kozuka, J. Sol-Gel. Sci. Technol. 42, 221 (2007).

A.M. Azad, M. Hashim, and S. Baptist, J. Mater. Sci. 35, 5475 (2000).

S. Song, J. Zhai, L. Gao, X. Yao, and J. Phys, Chem. Solids 70, 1213 (2009).

W. Lu and H. Schmidt, J. Sol-Gel. Sci. Technol. 42, 55 (2007).

Y. Wang, A. Chesnaud, E. Bevillon, J. Yang, and G. Dezanneau, Int. J. Hydrog. Energy 36, 7688 (2011).

W. Lu and H. Schmidt, J. Eur. Ceram. Soc. 25, 919 (2005).

W. Lu and H. Schmidt, Ceram. Int. 34, 645 (2008).

N.U. Patil and G.H. Jain, in Proceedings of 6th International Conference on Sensing Technology (2013), pp. 433–447

M. Yasukawa, T. Kono, K. Ueda, H. Yanagi, and H. Hosono, Mater. Sci. Eng., B 173, 29 (2009).

B. Ramdas and R. Vijayaraghavan, Bull. Mater. Sci. 33, 75 (2010).

E. Bevillon, A. Chesnaud, Y. Wang, G. Dezanneau, and G. Geneste, J. Phys. Condens. Matter 20, 145217 (2008).

R. Koferstein, L. Jager, M. Zenkner, and S.G. Ebbinghaus, J. Eur. Ceram. Soc. 29, 2317 (2009).

M.C.F. Alves, S.C. Souza, H.H.S. Lima, and M.R. Nascimento, J. Alloys Compd. 476, 507 (2009).

S. Sallis, D.O. Scanlon, S.C. Chae, N.F. Quackenbush, D.A. Fischer, J.C. Woicik, J.H. Guo, S.W. Cheog, and L.F.J. Piper, Appl. Phys. Lett. 103, 042105 (2013).

K.H. Joon, K.H. Min, K.T. Hoon, M.H. Sik, J. Byung-Gu, H.K. Teak, L. Woong-Jhae, J. Chanjong, K.K. Hoon, and C. Kookrin, Appl. Phys. Express 5, 061102 (2012).

M. Viviani, M.T. Buscaglia, V. Buscaglia, M. Leoni, and P. Nanni, J. Eur. Ceram. Soc. 21, 1981 (2002).

C. Huang, X. Wang, X. Wang, X. Liu, Q. Shi, X. Pan, and X. Li, RSC Adv. 6, 25379 (2016).

K.N. Singh and P.K. Bajpai, Int. J. Phys. Sci. 16, 37111 (2017).

R. Köferstein and F. Yakuphanoglu, J. Alloys Compd. 506, 678 (2010).

R. Köferstein, L. Jäger, M. Zenkner, T. Müller, and S.G. Ebbinghaus, J. Eur. Ceram. Soc. 30, 1419 (2010).

J. Cerda, J. Arbiol, G. Dezanneau, R. Dĺaz, and J.R. Morante, Sens. Actuators, B 84, 21 (2002).

V.J. Angadi, S.P. Kubrin, D.A. Sarychev, S. Matteppanavar, B. Rudraswam, H.L. Liu, and K. Praveena, J. Magn. Magn. Mater. 441, 348 (2017).

V.J. Angadi, B. Rudraswamy, K. Sadhana, and K. Praveena, J. Magn. Magn. Mater. 409, 111 (2016).

V.J. Angadi, L. Choudhury, K. Sadhanac, H.L. Liu, R. Sandhya, S. Matteppanavar, B. Rudraswamy, V. Pattar, R.V. Anavekar, and K. Praveena, J. Magn. Magn. Mater. 424, 01 (2017).

B. Hadjarab, A. Bouguelia, A. Benchettara, and M. Trari, J. Alloys Compd. 461, 360 (2008).

A.S. Bhalla, R. Guo, and R. Roy, Mater. Res. Innov. 4, 3 (2000).

S. Wang, H. He, and H. Su, J. Mater. Sci. Mater. Electron. 24, 2385 (2013).

P.S. Dobal, A. Dixit, and R.S. Katiyar, J. Raman Spectrosc. 38, 42 (2007).

M.A. Islam, J.M. Rondinelli, J.E. Spanier, and J. Physics, Condens. Matter 25, 175902 (2012).

A. Slodcyzk, P. Colomban, and M.P. Thi, J. Phys. Chem. Solids 69, 2503 (2008).

P.K. Bajpai, C.R.K. Mohan, R. Ganjir, R. Kumar, A. Kumar, and R.S. Katiyar, J. Raman Spectrosc. 49, 324 (2018).

A. Slodcyzk and P. Colomban, Materials 3, 5007 (2010).

M.T. Buscaglia, M. Leoni, M. Viviani, and V. Buscaglia, J. Mater. Res. 18, 560 (2002).

K.K. James, P.S. Krishnaprasad, K. Hasna, and M.K. Jayaraj, J. Phys. Chem. Solids 76, 64 (2015).

T.N. Stanislavchuk, A.A. Sirenko, A.P. Litvinchuk, X. Luo, and S.-W. Cheong, J. Appl. Phys. 112, 044108 (2012).

L.F. Zhu, B.P. Zhang, L. Zhao, and J.F. Li, J. Mater. Chem. C 2, 4764 (2014).

H.B. Sales, V. Bouquet, S. Députier, S. Ollivier, and F. Gouttefangeas, Solid State Sci. 28, 67 (2014).

Acknowledgments

Facilities developed under Special assistance program of University Grants Commission, New Delhi and FIST program of Department of Science and Technology, Govt. of India in the Department of Pure and Applied Physics are gratefully acknowledged. Sharmila Bajpai is grateful to Guru Ghasidas Vishwavidyalaya, Bilaspur, India for providing Non-NET fellowship.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bajpai, S., Bajpai, P.K. Local Symmetry Reduction in Lanthanum Substituted Barium Stannate Ceramics Densified Using Bi2O3 Sintering Aids. J. Electron. Mater. 48, 6306–6318 (2019). https://doi.org/10.1007/s11664-019-07437-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-019-07437-7