Abstract

The use of tools with chamfered cutting edges is an essential part of high performance cutting (HPC) as a rough milling process strategy for manufacturing structural components in the aerospace industry. Due to an interaction between the chamfer and the undulated workpiece surface, tool vibrations can be damped allowing high depths of cut without the occurrence of harmful dynamic effects. Hence, a significant increase in efficiency is possible. As a result of process damping, the stability boundary predicted by linear stability analysis provided for instance by analytical or geometric physically-based simulations will generally underestimate the experimentally determined one. Consequently, the object of this procedure, namely to reduce the number of test runs until sufficient process parameter values are determined, could not be met. Therefore, the damping effect induced by chamfered tools was analysed in this paper. It is shown that the use of chamfered cutting edges leads to a significant limitation of chatter amplitudes when exceeding the stability limit. The strength of this effect depends on the cutting speed and the engagement situation, which influence the intensity and number of interactions between the chamfer and the workpiece surface and, thus, the resulting process damping. Moreover, a dynamic process damping model presented in the literature was chosen and implemented in a geometric physically-based milling simulation. An evaluation of its validity points out the challenges regarding the simulation of process damping.

Similar content being viewed by others

References

Martin P (2013) Produktion im Flugzeugbau—technisch anspruchsvolle Herstellungsverfahren in komplexen Leistungserbringungsprozessen, Impulsgeber Luftfahrt. In: Hinsch M, Olthoff J (eds) Industrial Leadership durch luftfahrtspezifische Aufbau- und Ablaufkonzepte. Springer, Berlin Heidelberg, pp 159–189

Lange M (2005) Hochleistungsfräsen von Aluminium-Bauteilen für den Flugzeugbau. In: Weinert K (ed) Spanende Fertigung, 4th edn. Vulkan, Essen, pp 59–67

Lange M (2012) Herausforderungen bei der spanenden Hochleistungsbearbeitung metallischer Flugzeugbauteile. In: Biermann D (ed) Spanende Fertigung, 6th edn. Vulkan, Essen, pp 67–76

Sellmeier V (2012) Über den Einfluss der Werkzeuggestalt auf die dynamische Stabilität des Fräsprozesses. Dissertation, Gottfried Wilhelm Leibnitz University Hannover

Sellmeier V, Denkena B (2012) High speed process damping in milling. CIRP J Manuf Sci Technol 5:8–19

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. Ann CIRP 53(2):619–642

Munoa J, Beudaert X, Dombovari Z et al (2016) Chatter suppression techniques in metal cutting. Ann CIRP 65(2):785–808

Altintas Y (2012) Manufacturing automation, 2nd edn. Cambridge University Press, Cambridge

Insperger T, Stepan G (2002) Semi-discretization method for delayed systems. Int J Numer Methods Eng 55:503–518

Schmitz TL, Smith KS (2009) Machining dynamics. Springer, New York

Surmann T (2005) Geometrisch-physikalische Simulation der Prozessdynamik für das fünfachsige Fräsen von Freiformflächen, Dissertation, Technical University of Dortmund

Wu DW (1989) A new approach of formulating the transfer function for dynamic cutting processes. ASME J Eng Ind 111:37–47

Sisson TR, Kegg RL (1969) An explanation of low-speed chatter effects. J Eng Ind 91(4):951–958

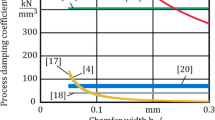

Altintas Y, Eynian M, Onozuka H (2008) Identification of dynamic cutting force coefficients and chatter stability with process damping. Ann CIRP 57:371–374

Tyler CT, Troutman JR, Schmitz TL (2016) A coupled dynamics, multiple degree of freedom process damping model, Part 2: milling. Precis Eng 46:73–80

Ahmadi K, Ismail F (2011) Analytical stability lobes including nonlinear process damping effect on machining chatter. Int J Mach Tools Manuf 51(4):296–308

Ahmadi K, Ismail F (2012) Stability lobes in milling including process damping and utilizing multi-frequency and semi-discretization methods. Int J Mach Tools Manuf 54–55:46–54

Budak E, Tunc LT (2009) A new method for identification and modeling of process damping in machining. J Manuf Sci Eng 131(5):1–10

Budak E, Tunc LT (2010) Identification and modeling of process damping in turning and milling using a new approach. Ann CIRP 59:403–408

Tunc LT, Budak E (2012) Effect of cutting conditions and tool geometry on process damping in machining. Int J Mach Tools Manuf 57:10–19

Ahmadi K, Altintas Y (2014) Identification of machining process damping using output-only modal analysis. J Manuf Sci Eng 136(5):051017-1–051017-13

Surmann T (2017) Simulation der Dynamik von Dreh- und Fräsprozessen. Vulkan, Essen

Foley J, Feiner S, Hughes J (1993) Introduction to computer graphics. Addison-Wesley, Reading

Weinert K, Surmann T (2003) Geometric simulation of the milling process for free formed surfaces. In: Weinert K (ed) Simulation aided offline process design and optimization in manufacturing sculptured surfaces, Witten 27:21–30

Kienzle O (1952) Die Bestimmung von Kräften und Leistungen an spanenden Werkzeugen und Werkzeugmaschinen. VDI-Z 94(11):299–305

Haake F (1982) Einführung in die Theoretische Physik. Physik-Verlag, Weinheim

Surmann T, Biermann D, Kehl G (2008) Oscillator model of machine tools for the simulation of self excited vibrations in machining processes. In: Proceedings of the 1st international conference on process machine interactions, Hannover, Germany, pp 23–29

DIN 6580 (German Institute for Standardization) (1985) Terminology of chip removing; movements and geometry of the chip removing process. Beuth Verlag, Berlin

Denkena B, Bickel W, Grabowski R (2014) Modeling and simulation of milling processes including process damping effects. Product Eng 8:453–459

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wöste, F., Baumann, J., Wiederkehr, P. et al. Analysis and simulation of process damping in HPC milling. Prod. Eng. Res. Devel. 13, 607–616 (2019). https://doi.org/10.1007/s11740-019-00912-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-019-00912-4