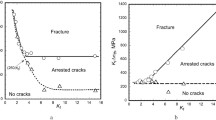

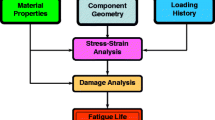

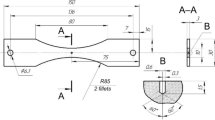

A model for evaluating the fatigue life of specimens/structure elements with sharp stress raisers/defects is presented. The model permits of computing the number of cycles to fatigue crack initiation and its growth from a sharp stress raiser to failure at a constant stress span with the only application of characteristics of static strength and microstructure of the initial material. The model can be used to assess the fatigue life of components that contain structural stress raisers and defects stemming from their manufacturing technique (surface roughness, surface cuts, scratches, and microcracks). The model reliability was verified with experimental results taken from the literature, calculations appeared to be in good agreement with experimental data. Fatigue curves to a grain-size crack initiation and to fracture of smooth specimens and those with a chemically-notched blunt raiser that simulates the casting defects in aircraft components were calculated. The two sets of specimens from a Ti–6Al–4V titanium alloy differing in the cross-section (rectangular and cylindrical) and in microstructure (different grain sizes). Smooth specimens exhibited the test surface roughness Rv = 10 and 19 μm (average dent depth), which was assumed to be a sharp raiser for calculations. The model need not long-term and labor-consuming high-cycle fatigue tests to construct the fatigue curve.

Similar content being viewed by others

References

O. M. Herasymchuk, O. V. Kononuchenko, P. E. Markovsky, and V. I. Bondarchuk, “Calculating the fatigue life of smooth specimens of two-phase titanium alloys subject to symmetric uniaxial cyclic load of constant amplitude,” Int. J. Fatigue, 83, 313–322 (2016).

O. M. Herasymchuk, “Nonlinear relationship between the fatigue limit and quantitative parameters of material microstructure,” Int. J. Fatigue, 33, 649–659 (2011).

O. M. Herasymchuk, O. V. Kononuchenko, and V. I. Bondarchuk, “Fatigue life calculation for titanium alloys considering the influence of microstructure and manufacturing defects,” Int. J. Fatigue, 81, 257–264 (2015).

K. S. Chan, “A microstructure-based fatigue-crack-initiation model,” Metall. Mater. Trans. A, 34, 43–58 (2003).

P. Lukáš and M. Klesnil, “Fatigue limit of notched bodies,” Mater. Sci. Eng., 34, 61–66 (1978).

H. Kitagawa and S. Takahashi, “Applicability of fracture mechanics to very small cracks or the cracks in the early stage,” in: Proc. of the Second Int. Conf. of Mechanical Behavior of Materials (August 16–20, 1976, Boston, MA), ASM, Metals Park, OH (1976), pp. 627–631.

O. M. Herasymchuk, “Modified KT-diagram for stress raiser-involved fatigue strength assessment,” Strength Mater., 50, No. 4, 608–619 (2018).

M. D. Chapetti, “Fatigue propagation threshold of short cracks under constant amplitude loading,” Int. J. Fatigue, 25, 1319–1326 (2003).

J. Maierhofer, H. P. Gänser, and R. Pippan, “Modified Kitagawa–Takahashi diagram accounting for finite notch depths,” Int. J. Fatigue, 70, 503–509 (2015).

M. H. El Haddad, T. H. Topper, and K. N. Smith, “Prediction of non propagating cracks,” Eng. Fract. Mech., 11, No. 3, 573–584 (1979).

O. M. Herasymchuk, “Relationship between the threshold stress intensity factor ranges of the material and the transition from short to long fatigue crack,” Strength Mater., 46, No. 3, 368–374 (2014).

K. S. Chan, “Variability of large-crack fatigue-crack-growth thresholds in structural alloys,” Metall. Mater. Trans. A, 35, 3721–3735 (2004).

BS 7910:2005. Guide to Methods for Assessing the Acceptability of Flaws in Metallic Structures, British Standard, BSI (2205).

R. W. Hertzberg, “A simple calculation of da/dN − ΔK data in the near threshold regime and above,” Int. J. Fracture, 64, R53–R58 (1993).

O. M. Herasymchuk, “Microstructurally-dependent model for predicting the kinetics of physically small and long fatigue crack growth,” Int. J. Fatigue, 81, 148–161 (2015).

A. J. McEvily, M. Endo, and Y. Murakami, “On the \( \sqrt{area} \) relationship and the short fatigue threshold,” Fatigue Fract. Eng. Mater. Struct., 26, 269–278 (2003).

K. Sadananda, S. Sarkar, D. Kujawski, and A. K. Vasudevan, “A two-parameter analysis of S–N fatigue life using Δσ and σmax,” Int. J. Fatigue, 31, 1648–1659 (2009).

C. A. Rodopoulos, J.-H. Choi, E. R. de los Rios, and J. R. Yates, “Stress ratio and the fatigue damage map –Part I: Modelling,” Int. J. Fatigue, 26, 739–746 (2004).

C. A. Rodopoulos, J.-H. Choi, E. R. de los Rios and J. R. Yates, “Stress ratio and the fatigue damage map – Part II: The 2024-T351 aluminium alloy,” Int. J. Fatigue, 26, 747–752 (2004).

G. Léopold, Y. Nadot, T. Billaudeau, and J. Mendez, “Influence of artificial and casting defects on fatigue strength of moulded components in Ti-6Al-4V alloy,” Fatigue Fract. Eng. Mater. Struct., 38, 1026–1041 (2015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 3, pp. 47 – 61, May – June, 2019.

Rights and permissions

About this article

Cite this article

Herasymchuk, O.M., Novikov, A.I. Microstructure-Based Model for Sharp Stress Raiser-Related Fatigue Stage Length Assessment. Strength Mater 51, 361–373 (2019). https://doi.org/10.1007/s11223-019-00082-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-019-00082-9