Abstract

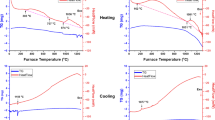

Mass loss and direct reduction characteristics of iron ore-coal composite pellets under different technological parameters were investigated. Meanwhile, changes of iron phase at different temperatures were analyzed by using X-ray diffraction (XRD), and characteristics of crushed products were studied by using a scanning electron microscope (SEM). The results showed that heating rate had little influence on the reduction, but the temperature played an important role in the reduction process. The mass loss rate increased rapidly from 800 to 1100 °C. The reduction process can be divided into three steps which correspond to different temperature ranges. Fe2O3 began to transform into Fe3O4 below 500 °C, and FeO was reduced into Fe from 900 °C. At 900 °C, the reduction product showed a clear porous structure, which promoted the reduction progress. At 1000 °C, the metallic Fe dominated the sample, and the reduction reached a very high degree.

Similar content being viewed by others

References

Y. L. Ding, N. A. Warner, Ironmak. Steelmak. 24 (1997) 283–287.

H. V. Duong, R. F. Johnston, Ironmak. Steelmak. 27 (2000) 202–206.

O. P. Chukwuleke, J. J. Cai, S. Chukwujekwu, S. Xiao, J. Iron Steel Res. Int. 16 (2009) No. 2, 1–5.

E. Donskoi, R. I. Olivares, D. L. S. McElwain, L. J. Wibberley, Ironmak. Steelmak. 33 (2006) 24–28.

Q. Zhuang, B. Clements, J. Aota, L. Morin, Ironmak. Steelmak. 33 (2006) 429–432.

S. Haider, R. J. Fruehan, Metall. Mater. Trans. B 39 (2008) 784–795.

S. Haider, R. J. Fruehan, Metall. Mater. Trans. B 39 (2008) 796–808.

S. Haider, R. J. Fruehan, Metall. Mater. Trans. B 39 (2008) 809–817.

R. H. Tien, E. T. Turkdogan, Metall. Trans. B 8 (1977) 305–313.

N. S. Srinivasan, A. K. Lahiri, Metall. Trans. B 6 (1975) 269–274.

Z. L. Xue, J. Z. You, G. F. Zhou, J. Iron Steel Res. Int. 7 (2000) No. 2, 6–10.

N. S. Srinivasan, Powder Technol. 124 (2002) 28–39.

T. Coetsee, P. C. Pistorius, E. E. de Villiers, Minerals Eng. 15 (2002) 919–929.

J. Y. Shi, E. Donskoi, D. L. S. McElwain, L. J. Wibberley, Math. Comput. Modelling 42 (2005) 45–60.

D. Mohanty, A. Chandra, N. Chakraborti, Comp. Mater. Sci. 45 (2009) 181–188.

G. M. Chowdhury, G. G. Roy, Comp. Mater. Sci. 45 (2009) 176–180.

M. Kawanari, A. Matsumoto, R. Ashida, K. Miura, ISIJ Inter. 51 (2011) 1227–1233.

A. Ghosh, Trans. Indian Inst. Met. 66 (2013) 71–77.

X. Y. Ma, M. F. Jiang, Q. Wang, X. H. Wang, J. Northeast. Univ. Nat. Sci. 23 (2002) 440–443.

D. Q. Zhu, V. Mendes, T. J. Chun, J. Pan, Q. H. Li, J. Li, G. Z. Qiu, ISIJ Int. 51 (2011) 214–219.

Z. C. Huang, L. Y. Yi, T. Jiang, Powder Technol. 221 (2012) 284–291.

O. Sivrikaya, A. Í. Arol, Int. J. Miner. Process. 110–111 (2012) 90–100.

N. A. El-Hussiny, M. E. H. Shalabi, Powder Technol. 205 (2011) 217–223.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by Fundamental Research Funds for the Central Universities of China (FRF-SD-12-007B); National Science and Technology Support Plan in the 12th Five-year of China (2011BAE13B09)

Rights and permissions

About this article

Cite this article

Man, Y., Feng, Jx., Chen, Ym. et al. Mass Loss and Direct Reduction Characteristics of Iron Ore-Coal Composite Pellets. J. Iron Steel Res. Int. 21, 1090–1094 (2014). https://doi.org/10.1016/S1006-706X(14)60188-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(14)60188-6